Usually ships within 3-5 business days

Miller® FILTAIR® Capture 5 208/230 V, 10 ft. Arm

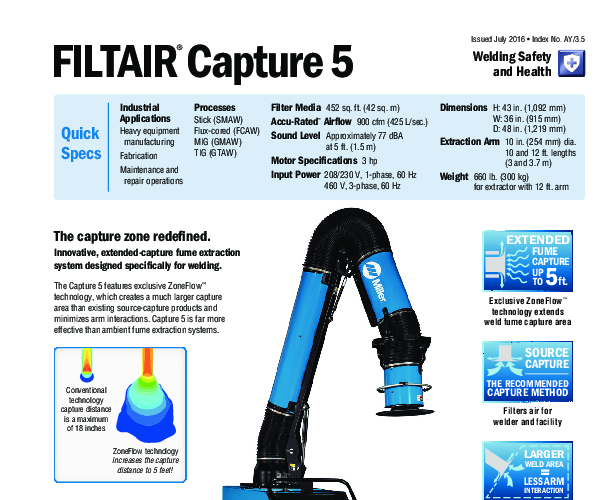

The Capture Zone, redefined. Innovative, extended-capture, fume extraction system designed specifically for welding. Exclusive ZoneFlow™ technology creates a much larger capture area than existing source-capture products. Ideal for fabrication shops, manufacturing and training centers.

Capture 5 Arm with ZoneFlow™ Technology: Creates a negative pressure zone that funnels air to the center of the arm from greater distances, up to 5 feet away. The arm features convenient 360-degree rotation for unlimited positioning, which means fewer hood adjustments and extended welding time. Less Arm Movement: With a capture zone that is 3 times larger than traditional systems, users have less interaction with the arm, increasing arc-on time and productivity. Pre-Assembled Arm: Made of aluminum and steel it is extremely durable for long-lasting performance. Balanced Arm Design: The arm is easy to move and stays in position. All adjustments are toolless and can be quickly adjusted by hand. Easy-to-Operate Extraction Arm: With external adjustments, air can pass through with less airflow resistance, giving you stronger cfm (airflow). It offers reliable and accurate positioning across the full range of motion of the arm, as well as easy adjustment and maintenance to ensure long-lasting operation. Pre-assembled extraction arms are available in 10 and 12 foot lengths. MERV 15 Filter Rating: Filters are rated on a MERV scale, which measures filter efficiency based on particle count. MERV ratings range from 1-16, with 16 being the best at filtering small particles-such as those found in weld fumes. FilTek® XL Filter Technology: FilTek XL Filter Technology is specifically designed for welding fumes. This technology offers a longer filter life - up to 2 times that of treated cellulous filters and superior filtering of up to 95% of weld fume particulate. Automatic Filter Cleaning: Extends filter life. Automatic pulse cleaning cycle cleans the filter from the inside out every time the machine is turned off. Weld fume particulate is removed from the filter and safely deposited in the disposal drawer. The manual push button and filter cleaning gauge ensures full control for highest airflow and consistent fume extraction throughout the life of the filter. Particulate Disposal Bin: Provides easy and convenient access to empty out collected particulate. Handles release drawer allowing it to slide out. Metal Cabinet Design: Ensures long-lasting durability in a manufacturing environment. Hinged Filter Hatch: Features a convenient locking mechanism for easy access to the filter and tool-free replacement. Filter Pressure Gauge: Easy to read and indicates when the pressure drop increases and cartridge filter needs to be replaced. Convenient Air Connection: Used for dry compressed air supply. Compressed air is required to operate the cleaning mechanism. Easy On / Off Power Switch: Conveniently located for easy on / off access. Lockable Swivel Casters: Allow users to keep fume extraction system stationary during movement of the arm. Large Rear Wheels: Allow for easy movement from one work area to another.| Additional Information |

|---|

| Packaging Description:1 Per Ea |