Usually ships within 3-5 business days

Miller® Trailblazer® 325 (Kohler) EFI

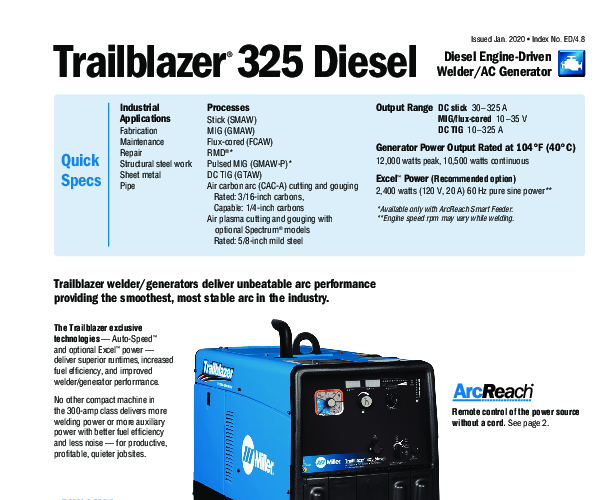

Trailblazer® engine-driven welders deliver unbeatable arc performance providing the smoothest, most stable arc in the industry. The Trailblazer exclusive Auto-Speed™ technology delivers superior runtimes, increased fuel efficiency, and improved engine-driven welder performance. No other compact machine in the 300-amp class delivers more welding power or more auxiliary power with better fuel efficiency and less noise — for productive, profitable, quieter jobsites.

Unbeatable arc performance: Wide amperage output with better welding deposition rates means youcan get jobs done faster, saving time and money. The Trailblazer also hasprecise arc control, which allows you to fine-tune the arc to match yourpersonal preferences and quickly dial in the perfect parameters tooptimize weld quality and maximize productivity across a variety ofapplications and welding processes. Auto-Speed™ Technology: Matches engine speed to load — a Miller exclusive. Get the weldingpower you need — plus reduced fuel consumption and lower noiselevels for a more-profitable, safer jobsite. Unlike competitive machines that operate at 3,600 rpm (max) under any load, Miller-exclusive Auto-Speed technology responds to weldrequirements by automatically adjusting engine speed to one of fourrpm levels so the engine never works harder than necessary. Refueling time and operating costs are reduced, which means moreproductivity and profitability. Plus everyone on the jobsite gets a betterworking environment because noise levels and exhaust emissionsare lowered. Electronic fuel injection (EFI) (option): Improve fuel efficiency for maximum productivity and profitability.Adding EFI to your Trailblazer engine-driven welder adds multiple benefits. With EFI, you’ll get faster, more-reliable starts in any weather —no choke adjustments needed. EFI-equipped Trailblazer machines arealso up to 42 percent more fuel efficient than standard carbureted models, improving profitability. Plus, refueling less frequently means you’ll spend more of your time welding, improving productivity. Excel™ power (option): Power at idle — a Miller exclusive. Unlike competitive machines thatprovide auxiliary power only at 3,600 rpm (max), Excel power delivers afull 2,400 watts (20 A) of 120-volt inverter-based, pure sine wave powerat all speeds, including idle. With Excel power you can operate jobsitetools like grinders at quiet, fuel-saving speeds. Refueling time and operating costs are reduced with Excel power, whichmeans more productivity and profitability. Plus everyone on the jobsite gets a better working environment because noise levels and exhaust emissions are lowered. Excel power — available only from Miller. ArcReach® Technology: ArcReach technology uses existing weld cables to communicate process adjustment commands back to the engine-driven welder. With an ArcReach system, amperage & voltage are conveniently located at the operator's fingertips - not back at the power source. Cleaner and Stronger Auxiliary Power: Combined with a 25-horsepower engine, Trailblazer engine-driven weldersoffer up to 12,000 watts of clean, truly usable auxiliary power that isAccu-Rated™, not inflated: tested to deliver uninterrupted peak output fora minimum of 30 seconds for big loads, so you can get more jobs done.An independent welder and auxiliary power system ensures nointeraction between jobsite tools and the welding arc, while advancedauxiliary power technology virtually eliminates power spikes and other electrical imperfections — so welds are cleaner and jobsite tools can run without interruption, maximizing quality, productivity and profit. Fewer refueling trips: No other gas engine-driven welder in the 300-amp class lets your crewsspend more time working and less time refueling — because onlyTrailblazer engine-driven welders provide Auto-Speed™ technology, plusExcel™ power and electronic fuel injection (EFI) options, to delivermaximum runtime. Maximum cost savings: Less money spent on fuel means more profit for you. Every Miller Trailblazer engine-driven welder has fuel-saving Auto-Speed technology; add optional Excel power and Electronic Fuel Injection (EFI) to save even more on fuel costs and enjoy a combination of advanced, profit-enhancing features that are only available on a Trailblazer engine-driven welder. Safer, more productive jobsites: Quieter jobsites are safer and more productive because work crews cancommunicate easier, and work can start earlier and end later — even innoise-sensitive areas. If your jobsite requires welding/auxiliary power, it needs aTrailblazer engine-driven welder — because no other gas-fueled choice isas quiet. More mobile, uses less truck and jobsite space: Trailblazer engine-driven welders are up to 17 percent smaller and10 percent lighter then competitive machines — which means movingthem is faster and easier, for maximum productivity. And becausethey take up less space, Trailblazer engine-driven welders let work truckscarry more equipment and gear — so your work crews can be readyfor anything. ArcReach Heater Compatibility: Take charge of your field preheat and bakeout applications up to 600 degrees Fahrenheit (315°C). This system uses induction heating to generate heat in workpieces, so welders can do their own preheating quickly and safely. A part of the ArcReach technology platform, the ArcReach Heater is an accessory for select ArcReach welding power sources.| Additional Information |

|---|

| Packaging Description:1 of each |

| Weld Process:Engine Drive |

| Brand:Miller |

| Voltage:n/a |

| Amps:325 |

| Duty Cycle:100 |

| Watts:12000 |

| Cutting Capacity:n/a |