Tactile seam tracking systems provide precise automated seam tracking for a variety of welding processes, including submerged arc, GMAW, FCAW, and GTAW. These systems are highly recommended for repetitive welding applications, as they enhance quality and consistency while reducing operational costs. Standard systems and personalized solutions are available to meet the demanding requirements of different production environments.

Setting up and operating these systems is effortless and user-friendly. Operators can quickly learn to program and operate them. Additionally, the selection of system components is straightforward, with pre-configured options available. These include choosing the level of automation, selecting the appropriate cross slide assembly based on load capacity, determining the necessary travel stroke length for each axis, and picking the suitable application-specific seam sensor tip.

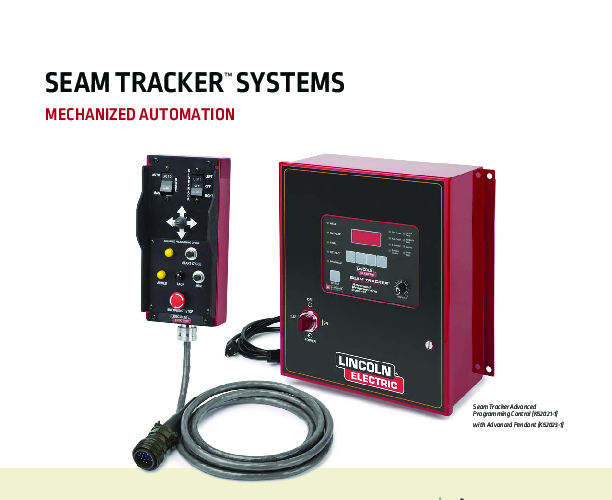

For advanced capabilities, the system offers an Advanced Programming Control (APC). With the APC, users can program the entire weld cycle sequence based on position or time, and store up to 19 different weld sequence programs.

Furthermore, these systems can be integrated with almost any welding power source, feeder, and controlled group, allowing for widespread compatibility and flexibility.

Please note that the video content is not included in the description.

| Additional Information |

|---|

| Packaging Description:1 Per Ea |