What You Need to Know About Specialty Gases

April 15, 2025 7:31 pmSpecialty gases represent a class of gases meticulously produced, rigorously purified, or precisely mixed to meet exacting standards of high purity or specific compositional requirements. These gases, unlike their more common industrial counterparts, are tailored for applications demanding exceptional levels of quality and control. Their significance resonates across a multitude of industries, underpinning critical processes in research, manufacturing, and technology. This article provides a comprehensive overview of specialty gases, addressing their fundamental characteristics, diverse applications, and essential handling considerations.

What are Specialty Gases?

Specialty gases are distinguished from industrial gases such as nitrogen, oxygen, and argon primarily by their emphasis on purity, precise mixture ratios, and unique properties. While industrial gases are produced in large volumes for general applications, specialty gases are manufactured in smaller quantities with a focus on meeting specific, often stringent, requirements.

Examples of common specialty gases include helium, neon, krypton, xenon, a range of calibration gases, various rare gases, and electronic gases used in semiconductor manufacturing. Some specialty gases occur naturally and are extracted from the atmosphere or natural gas deposits, while others are synthesized through specific chemical processes. The defining characteristic is their engineered nature to fulfil niche but critical roles.

Key Properties and Characteristics

Specialty gases possess several key properties that dictate their suitability for specific applications. Understanding these characteristics is crucial for selecting and utilizing these gases effectively and safely.

- Purity Levels

Specialty gases’ purity is crucial for accurate results and preventing interference. Measurements of impurities in ppm or ppb indicate low levels of contaminants. High purity is essential in analytical applications, such as semiconductor manufacturing, to ensure reliable data.

- Mixture Accuracy

The National Research Council of Canada (NRC) is a leading provider of certified reference materials and expertise in gas metrology, which are crucial for calibration and environmental monitoring applications. These mixtures, known as certified reference materials, are meticulously controlled and verified, ensuring the accuracy and reliability of gas mixtures used across various Canadian sectors.

- Stability and Shelf Life

The stability of specialty gases over time is an important consideration. Factors such as the reactivity of the gas, the material of the cylinder, and storage conditions can affect stability. Some gases may degrade or react with the cylinder walls over time, altering their composition. Proper storage, typically in controlled environments away from extreme temperatures and corrosive materials, is essential to maintain gas stability and ensure the stated shelf life.

- Reactivity and Safety Considerations

Specialty gases, including flammable and toxic gases, pose specific hazards and require careful handling to prevent fires or explosions. Corrosive gases like chlorine and ammonia can damage equipment and pose health risks. Comprehensive safety data sheets (SDS) outline hazards, precautions, and emergency procedures. Adherence to guidelines from organizations like the Compressed Gas Association (CGA) is crucial for safe handling and storage of these gases.

Common Applications Across Industries

Specialty gases find diverse applications across a wide spectrum of industries, driven by their unique properties and high purity.

- Healthcare: Specialty gases play a vital role in medical applications. Helium is used in magnetic resonance imaging (MRI) machines to cool superconducting magnets. Nitrous oxide serves as an anaesthetic. High-purity oxygen mixtures are used for respiratory therapy. Calibration gases are essential for ensuring the accuracy of medical diagnostic equipment. The Canadian Standards Association (CSA) sets standards for medical gases and related equipment, highlighting the critical role of specialty gases in healthcare.

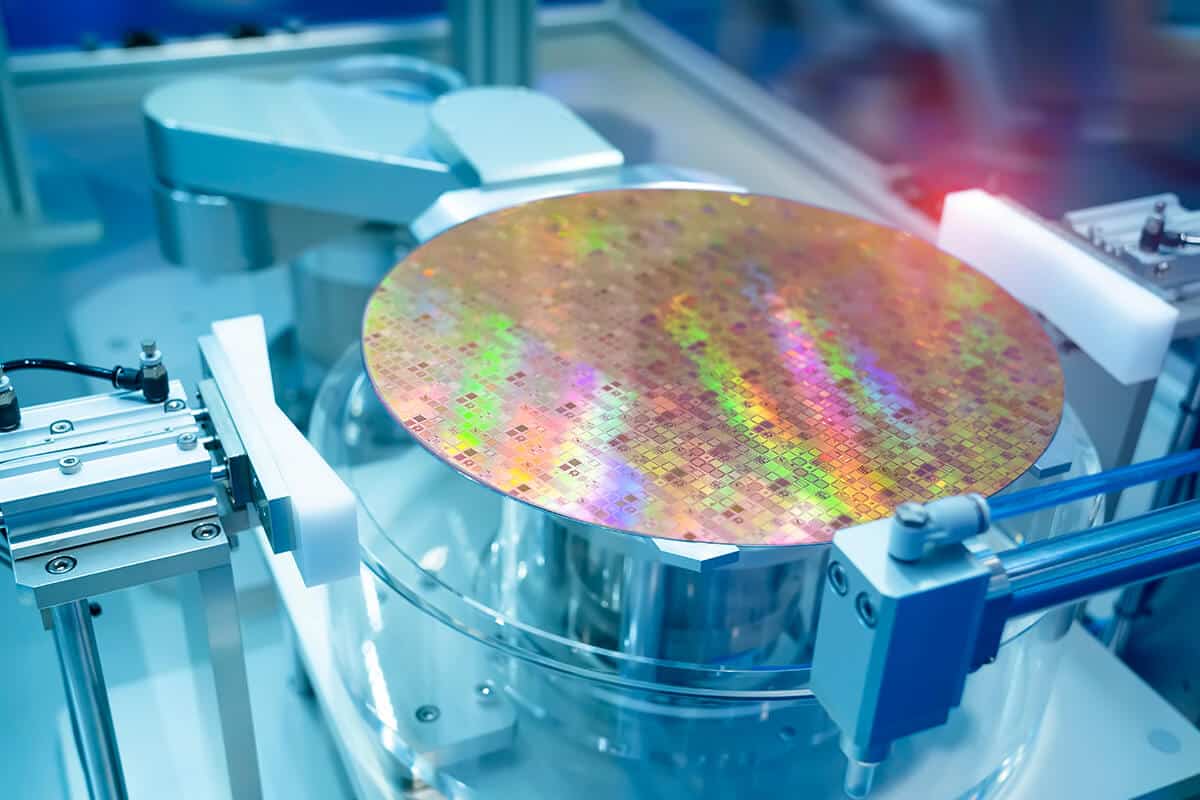

- Electronics and Semiconductor Manufacturing: The electronics industry relies heavily on specialty gases for various manufacturing processes. High-purity gases like silane, ammonia, and various fluorinated gases are used in etching, deposition, and doping processes crucial for producing semiconductors, integrated circuits, and flat panel displays. Impurities can significantly impact device yield and performance, underscoring the need for ultra-high purity gases.

- Environmental Monitoring: Specialty gases are fundamental to environmental monitoring and analysis. Calibration gas mixtures are used to calibrate instruments that measure air and water quality, ensuring the accuracy of data on pollutants and greenhouse gases. Gases like sulphur dioxide, nitrogen oxides, and carbon monoxide are routinely monitored using instruments calibrated with specialty gas standards. Environment and Climate Change Canada utilizes certified reference materials for air quality monitoring programs across the country.

- Research and Development: Specialty gases are indispensable tools in scientific research and development across various disciplines. They are used in spectroscopy, chromatography, laser technology, and materials science. Rare gases like argon and helium provide inert atmospheres for experiments. Specific gas mixtures are used to study chemical reactions and material properties. Universities and research institutions across Canada rely on the precise properties of specialty gases for cutting-edge research.

- Aerospace and Automotive Industries: These industries employ specialty gases for testing, calibration, and manufacturing processes. Helium is used for leak detection in pipelines and fuel systems. Calibration gases are essential for engine emission testing. Argon is used in welding processes to create inert atmospheres. The automotive sector employs specialty gases for airbag inflation systems and the calibration of sensors.

Specialty gases are indispensable components across a multitude of industries, enabling critical processes that demand high purity, precise mixtures, and specific properties. From healthcare and electronics to environmental monitoring and research, these gases underpin technological advancements and ensure the accuracy of vital measurements. Understanding their key characteristics and adhering to stringent safety protocols are essential for their effective and safe utilization. For reliable supply and expert advice on specialty gases, contact Josef Gases at (416) 658-1212.