Precision Gas Mixtures: Optimizing Processes for Industrial Uses

March 21, 2025 8:06 pmPrecision gas mixtures are defined as combinations of gases with precisely controlled proportions, ensuring accuracy and consistency. These mixtures are critical across numerous industries, including manufacturing, environmental monitoring, and healthcare. The accuracy of these specialty gases directly influences process efficiency and product quality. Optimal process optimization is achieved through meticulous control of gas mixture composition. This article discusses the fundamentals of gas mixture creation, the industries that rely on these mixtures, the impact on process optimization, and the challenges associated with their selection and handling.

The Fundamentals of Gas Mixture Composition

Gas mixture composition is determined by the specific gases included and their precise volumetric or molar ratios. Precision when creating these mixtures is paramount for consistent industrial applications.

Key Components of a Gas Mixture

- Individual Gases: This refers to the specific types of gases that make up the mixture. Examples include nitrogen, oxygen, carbon dioxide, argon, and various other gases. The properties of the mixture are directly influenced by the types of gases present.

- Concentrations: This component describes the amount of each individual gas within the mixture. Concentrations are typically expressed as percentages or parts per million (ppm). Precise control of these concentrations is crucial for achieving the desired properties and performance of the gas mixture.

- Purity: The purity of each individual gas component is essential. Impurities can significantly affect the overall accuracy and stability of the gas mixture. High-purity gases minimize the risk of unwanted reactions or deviations in performance.

- Partial Pressures: In a gas mixture, each individual gas exerts a pressure. This is known as partial pressure. The sum of the partial pressures equals the total pressure of the gas mixture. This is an important concept in understanding how gases behave in a mixture.

- Ratios: The ratios of the gasses in the mixture are a key component. The ratio of one gas to another will drastically change the properties of the overall gas mixture.

Blending Methods

When creating gas mixtures, precision is paramount, and several methods are employed to achieve the desired composition.

- Gravimetric Methods: This method relies on accurately weighing each component gas. It’s known for its high accuracy, particularly in applications requiring precise mass ratios. This is very important for calibration gases.

- Volumetric Methods: This involves measuring the volume of each gas at controlled temperature and pressure. It’s a common technique often used when volumetric ratios are critical. Partial pressure blending is a subtype of this method.

- Dynamic Blending: This method involves continuously mixing gases at controlled flow rates. It’s suitable for applications requiring a continuous supply of a specific gas mixture. Mass flow controllers are often used within this method.

These methods cater to different needs, with factors like accuracy requirements, mixture complexity, and application type influencing the choice of method.

Key Industries Reliant on Precision Gas Mixtures

Numerous industries depend on the accuracy of precision gas mixtures for their operations.

- Environmental Monitoring: Environmental monitoring relies on calibration gas mixtures for accurate measurement of pollutants. These mixtures are used to calibrate instruments that monitor air and water quality. The accuracy of these measurements is crucial for regulatory compliance and public health.

- Petrochemical Industry: The petrochemical industry uses gas mixtures for process control and quality assurance. Specific mixtures are used in catalytic processes, combustion control, and product analysis. The precise composition of these mixtures ensures efficient and safe operations.

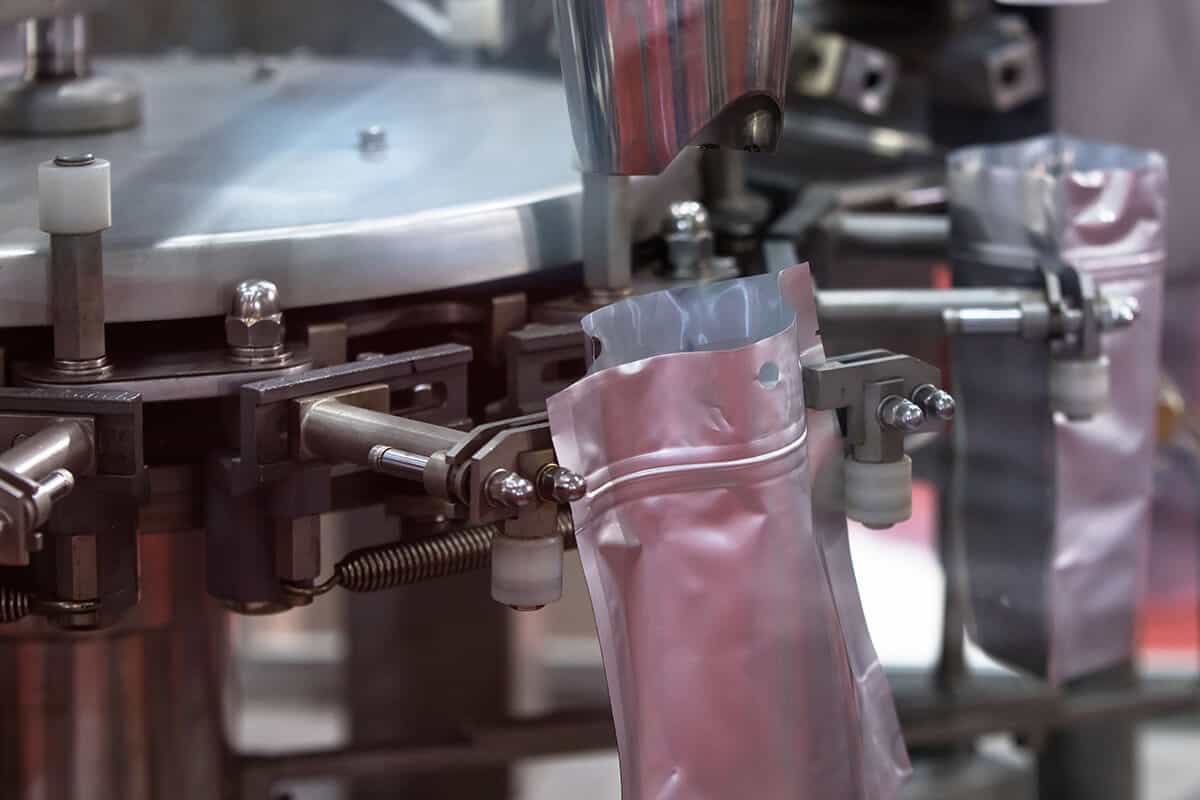

- Pharmaceutical Industry: The pharmaceutical industry utilizes gas mixtures for various applications, including controlled atmosphere packaging and calibration of analytical instruments. Accurate gas mixtures are essential for maintaining product integrity and ensuring regulatory compliance.

- Semiconductor Industry: The semiconductor industry requires ultra-high purity gas mixtures for fabrication processes. These mixtures are used in etching, deposition, and other critical steps. The purity and composition of these gases directly affect the quality and reliability of semiconductor devices.

- Food and Beverage Industry: The food and beverage industry uses modified atmosphere packaging (MAP) to extend the shelf life of products. Precise gas mixtures, such as combinations of nitrogen, carbon dioxide, and oxygen, are used to create optimal packaging environments.

- Welding Industry: The welding industry relies on shielding gas mixtures to protect the weld from atmospheric contamination. The composition of these mixtures affects the weld quality, strength, and appearance. Different welding processes require specific gas mixtures for optimal results.

- Medical Industry: The medical industry uses gas mixtures for respiratory therapy, anaesthesia, and calibration of medical devices. Accurate gas mixtures are essential for patient safety and treatment efficacy.

The Impact of Precise Gas Mixtures on Process Optimization

Precise gas mixtures contribute significantly to process optimization across industries.

- Improved Product Quality: Accurate and constant gas mixes result in higher-quality products. Precise gas compositions in manufacturing minimize faults and provide constant product attributes.

- Enhanced Process Efficiency: Improved control of the gas mixture leads to increased process efficiency. Predictable process results from a consistent gas composition cut down on waste and downtime.

- Reduced Operational Costs: Optimized gas use results in lower operating expenses. Accurate mixes reduce the need for rework and changes, which saves money.

- Increased Safety: In dangerous situations, controlled gas mixes provide increased safety. Safe working conditions and the avoidance of unexpected reactions are guaranteed by accurate mixes.

- Better Regulatory Compliance: Using certified gas mixtures improves regulatory compliance. Adherence to safety and environmental laws is ensured by precise measurements and regulated procedures.

- Enhanced Research and Development: Precise gas mixes lead to improved research and development capabilities. Consistent gas compositions yield accurate experimental results, promoting scientific progress.

- Improved Calibration and Measurement Accuracy: Accurate calibration gas mixtures lead to improved calibration and measurement accuracy. Reliable readings in analytical and monitoring applications are ensured by precise calibration.

Challenges and Considerations in Gas Mixture Selection and Handling

Selecting and handling gas mixtures present various challenges.

- Application-Specific Selection: Selecting the correct gas mixture requires understanding the specific application requirements. Factors such as gas purity, composition, and delivery pressure must be considered.

- Stability Management: Maintaining gas mixture stability is essential for accurate results. Gas mixtures can degrade over time due to reactions between components or interactions with container materials.

- Safe Cylinder Handling: Ensuring proper gas cylinder handling and storage is crucial for safety. Gas cylinders must be stored in well-ventilated areas and handled according to safety guidelines.

- System Calibration and Maintenance: Calibrating and maintaining gas delivery systems is vital for accurate gas flow and composition. Regular calibration ensures consistent performance.

- High-Purity Handling: Dealing with high-purity gases requires specialized equipment and handling procedures. Contamination must be minimized to maintain gas purity.

- Regulatory Adherence: Regulatory compliance adds complexity to gas mixture handling. Standards such as those from the Transportation of Dangerous Goods (TDG) regulations in Canada must be observed.

- Economic Evaluation: Cost considerations are a component of gas mixture selection. High-purity gases and complex mixtures carry a premium. Evaluating the necessity of the purity and complexity is important.

Precision gas mixtures are indispensable for optimizing processes across diverse industries. Their accuracy and consistency directly impact product quality, process efficiency, and regulatory compliance. Careful selection, handling, and maintenance of these mixtures are critical for achieving optimal results.

For expert assistance with precision gas mixtures and specialty gases, contact Josef Gases. We are the only independent gas supplier in Ontario with a specialty gas laboratory on site. Contact us at (416) 658-1212 today!