Nitrogen vs. CO2: Selecting the Optimal Gas for Industrial Uses

July 4, 2025 1:33 pmChoosing the correct industrial gas represents a pivotal decision impacting operational efficiency, safety protocols, and overall cost structure. Numerous gases fulfil critical roles across diverse industrial landscapes. Among these, nitrogen (N₂) and carbon dioxide (CO₂) stand out as two of the most extensively utilized, each possessing distinct characteristics that render them suitable for specific applications.

This guide examines the inherent properties of nitrogen and carbon dioxide, comparing their applications across various industrial sectors. Understanding these differences assists in determining the most appropriate gas for particular requirements.

Properties of Nitrogen (N₂)

Nitrogen, a non-reactive gas, makes up 78% of Earth’s atmosphere, crucial in preventing oxidation and combustion, and is often used in industrial production through cryogenic distillation.

- Inertness: Nitrogen does not readily react with other substances. This property makes it an excellent blanketing or purging gas to displace oxygen and moisture, preventing unwanted chemical reactions, including oxidation and corrosion, in sensitive processes and storage.

- Non-flammability: Nitrogen itself does not burn and does not support combustion. Its application is critical in creating safe atmospheres in potentially explosive environments, serving as a fire suppression medium by reducing oxygen concentration below combustion thresholds.

- Cryogenic Properties: Nitrogen has a very low boiling point (-196 °C). Its liquid form is a potent refrigerant. This cryogenic capability is exploited for rapid freezing, temperature control, and preservation in numerous industrial and scientific applications, including food processing and medical storage.

- High Purity Availability: Industrial processes often require gases of very high purity. Nitrogen can be produced to extremely high purity levels, essential for sensitive applications in electronics manufacturing and analytical instrumentation where trace contaminants could cause significant issues.

- Pressure Characteristics: Gaseous nitrogen is readily available at various pressures. This allows it to be used effectively for pneumatic applications, pressure testing, and as a propellant in different systems, providing a safe and stable source of pressure without inherent reactivity concerns.

- Safety Profile: While generally safe due to its inertness, nitrogen can displace oxygen in enclosed spaces, posing an asphyxiation risk. Proper ventilation and monitoring are essential when working with nitrogen, particularly in confined areas, to maintain safe oxygen levels for personnel.

Properties of Carbon Dioxide (CO₂)

Carbon dioxide, a naturally occurring gas, is composed of one carbon atom covalently bonded to two oxygen atoms and can be liquefied or solidified under pressure or temperature.

- Acidity: When dissolved in water, carbon dioxide forms carbonic acid. This slightly acidic nature is utilized in various processes, including beverage carbonation and water treatment, where a mild acid is beneficial for altering pH or dissolving certain substances.

- Solubility: Carbon dioxide exhibits moderate solubility in water and other solvents. This solubility is fundamental to its use in carbonated beverages, enhanced oil recovery, and certain chemical processes where it acts as a solvent or reactant phase.

- Triple Point: Carbon dioxide has a unique triple point where solid, liquid, and gas phases coexist (at -56.6 °C and 5.18 barg). This property influences its behaviour during phase transitions and dictates conditions for storage and handling as a liquid or solid.

- Non-flammability: Similar to nitrogen, carbon dioxide does not burn and acts as a fire suppressant. It is effective in extinguishing fires by displacing oxygen, particularly for liquid and electrical fires where water is unsuitable. This makes it a common fire extinguisher agent.

- Sublimation Property (Dry Ice): Solid carbon dioxide, known as dry ice, bypasses the liquid phase and sublimates directly into a gas at atmospheric pressure. This characteristic makes dry ice an excellent portable refrigerant, leaving no liquid residue, useful for transporting perishable goods and cryo-cleaning.

- Density: Carbon dioxide gas is denser than air. This property is advantageous in fire suppression systems where it can blanket a fire, excluding oxygen. It also influences its behaviour in enclosed spaces, where it can accumulate at lower levels, posing a potential asphyxiation hazard.

Common Industrial Uses of Nitrogen (N₂)

Nitrogen, a crucial gas in industrial operations, is widely available and inert, providing safety and enhancing product quality. The Canadian manufacturing sector heavily relies on nitrogen for various processes, with Statistics Canada data showing its essential consumable materials in various subsectors.

- Purging and Blanketing: Nitrogen is extensively used to purge pipelines, tanks, and vessels to remove unwanted gases or vapours, such as oxygen and moisture. It also provides an inert atmosphere (blanketing) over sensitive materials or processes to prevent oxidation or degradation during storage or transfer.

- Food Packaging: Modified Atmosphere Packaging (MAP) often uses nitrogen to displace oxygen in food packaging. This inhibits the growth of aerobic bacteria and slows down oxidation, significantly extending the shelf life of packaged foods like snacks, meats, and prepared meals.

- Electronics Manufacturing: In the fabrication of semiconductors and other electronic components, nitrogen is crucial for creating an inert atmosphere during critical manufacturing steps. This prevents oxidation and contamination that could damage sensitive microcircuitry, ensuring product reliability and performance.

- Chemical Processing: Nitrogen is used as a carrier gas, a cooling agent, and to provide an inert atmosphere in chemical reactors and processes. It helps control reaction rates, manage temperatures, and prevent hazardous situations by eliminating the risk of combustion or unwanted side reactions.

- Oil and Gas Industry: Nitrogen injection is used for enhanced oil recovery (EOR) by maintaining reservoir pressure or displacing oil. It is also used for purging pipelines, pressure testing, and fracturing operations, leveraging its inertness and ability to provide pressure.

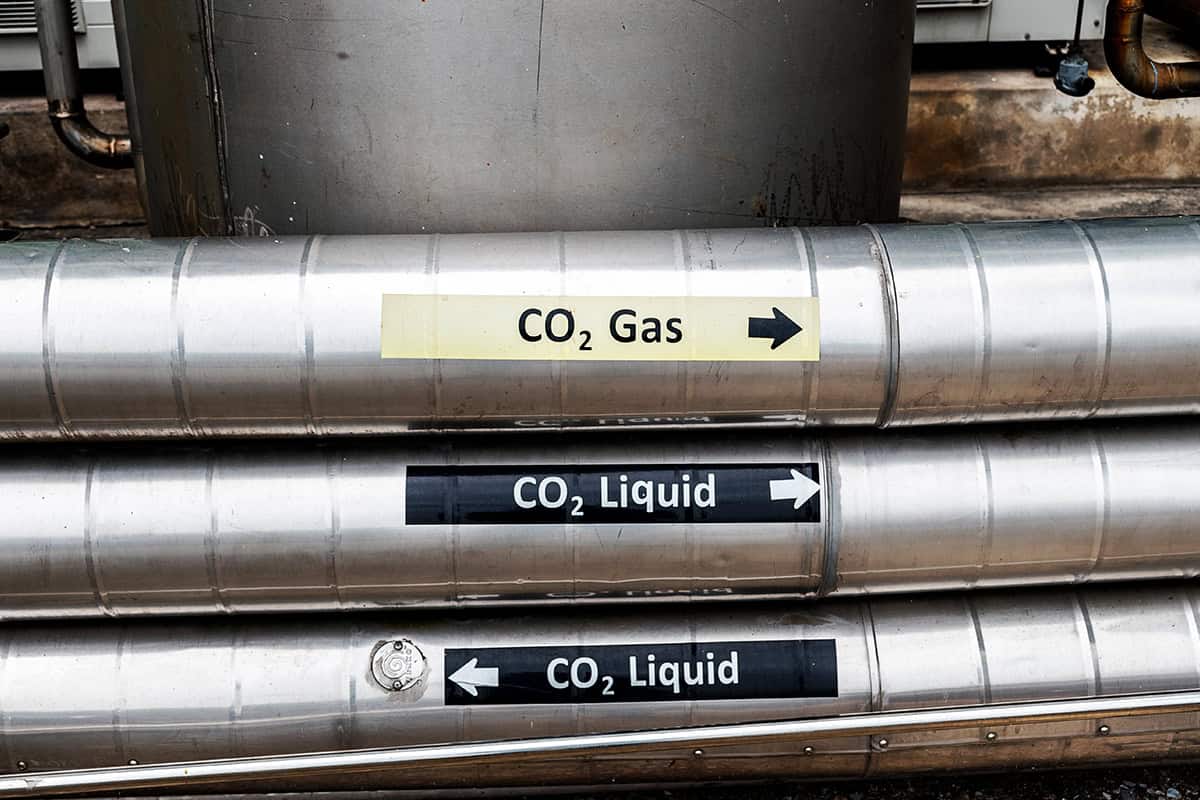

Common Industrial Uses of Carbon Dioxide (CO₂)

Carbon dioxide has various applications, including food and beverage production, environmental applications, and heavy industry. Environment and Climate Change Canada monitors greenhouse gas emissions, focusing on CO₂.

- Beverage Carbonation: Carbon dioxide is the gas responsible for the fizziness in carbonated drinks like soft drinks, beer, and sparkling wine. It dissolves under pressure, creating carbonic acid, which provides the characteristic bubbly texture and slightly tangy taste consumers expect.

- Fire Suppression: CO₂ is an effective fire extinguishing agent, particularly for Class B (flammable liquids) and Class C (electrical) fires. It works by displacing oxygen around the fire, smothering the flames without causing water damage or leaving residue, making it suitable for sensitive equipment.

- Dry Ice Production: Solid CO₂ (dry ice) is a powerful refrigerant used for transporting perishable goods, cryo-cleaning, and theatrical fog effects. Its ability to sublimate directly from solid to gas makes it a clean cooling agent, leaving no liquid waste behind.

- Welding Shielding Gas: In Metal Inert Gas (MIG) welding, a mixture of argon and carbon dioxide is commonly used as a shielding gas. The CO₂ helps stabilize the arc and improve weld penetration, particularly on steel, creating a protective atmosphere that prevents atmospheric contamination of the weld pool.

- Enhanced Oil Recovery (EOR): CO₂ injection is a method used to increase crude oil recovery from mature reservoirs. The injected CO₂ reduces oil viscosity and swells the oil, making it easier to extract. This process can significantly extend the productive life of oil fields.

Nitrogen vs. CO2: A Comparative Look

Nitrogen and carbon dioxide have distinct advantages and limitations in industrial applications, depending on process needs, safety, and cost. Their reactivity, phase behaviour, and properties influence optimal applications.

- Inertness vs. Reactivity: Nitrogen is highly inert, making it ideal for preventing reactions like oxidation. Carbon dioxide is mildly reactive (forming carbonic acid) and used where this reactivity is beneficial, such as in carbonation or pH adjustment processes.

- Phase Behaviour: Nitrogen remains a gas or liquid depending on temperature and pressure. Carbon dioxide has a readily accessible triple point and sublimes as a solid (dry ice), offering unique cooling and cleaning applications not possible with nitrogen.

- Density: Carbon dioxide is denser than air, advantageous for blanketing fires at lower levels. Nitrogen is slightly less dense than air, making it effective for purging lighter gases or providing upper-level inerting in vessels.

- Cryogenic Applications: Both can be used cryogenically, but liquid nitrogen’s extremely low boiling point makes it the primary choice for ultra-low temperature freezing and cooling applications where CO₂’s triple point limitations are restrictive at atmospheric pressure.

- Cost and Availability: Both gases are widely available industrially, often produced as byproducts or through air separation (nitrogen). Cost can vary based on purity requirements, quantity, location, and delivery method (bulk liquid, cylinders, or on-site generation).

Factors to Consider When Selecting Gas

Selecting nitrogen or carbon dioxide for industrial applications requires careful evaluation of factors like process requirements, safety standards, economic constraints, and environmental considerations, often consulting with industrial gas suppliers.

- Process Requirements: The fundamental needs of the industrial process dictate the required gas properties. Does the process need an inert atmosphere, a refrigerant, a mild acid, a source of pressure, or a fire suppressant? Matching gas properties to functional needs is paramount.

- Safety Considerations: Assess the safety implications of each gas in the specific operational environment. Consider risks like asphyxiation (for both gases, especially in confined spaces), pressure hazards, and the safe handling of cryogenic liquids or dry ice. Implement appropriate safety protocols.

- Purity Needs: The required purity level of the gas is critical, particularly in sensitive industries like electronics or food processing. High-purity gases come at a greater cost. Determine the minimum purity necessary to avoid product contamination or process interference.

- Storage and Handling: Evaluate the infrastructure needed for storing and handling the gas in its required phase (gas, liquid, or solid). Consider the space requirements for tanks or cylinders, the need for cryogenic equipment, and the safety procedures for handling pressurized or extremely cold substances.

- Cost Analysis: Conduct a comprehensive cost analysis considering the price of the gas itself, delivery costs, storage infrastructure investment, ongoing maintenance, and potential costs associated with safety measures and regulatory compliance. Compare the total cost of ownership for each option.

- Environmental Impact: Consider the environmental implications of gas use. While both are naturally occurring compounds, industrial production and use have environmental footprints. For CO₂, its role as a greenhouse gas is a factor, although industrial use as a product is distinct from direct emission.

- Regulatory Compliance: Ensure that the storage, handling, and use of the selected gas comply with all relevant local, provincial (e.g., Technical Standards and Safety Authority – TSSA in Ontario for pressure vessels), and federal regulations in Canada, including transportation guidelines and safety standards.

Each gas offers distinct advantages for different industrial challenges. The choice of nitrogen or carbon dioxide for industrial applications is a complex decision based on their unique chemical and physical properties. Nitrogen is essential for oxygen-free applications like food packaging and electronics manufacturing, while carbon dioxide is used in beverage carbonation, welding, and refrigeration. The choice depends on process requirements, safety, purity levels, logistics, economic factors, and regulatory frameworks.

For businesses operating in Canada requiring expert guidance on selecting the appropriate industrial gas, or for reliable supply solutions, contacting experienced providers is recommended. For specialty industrial gas needs, contact Josef Gases at (416) 658-1212.