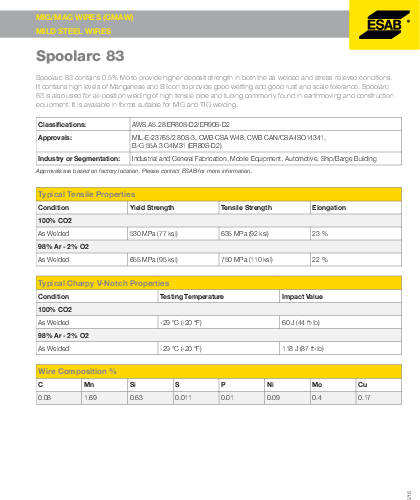

Spoolarc 83 is a reliable welding solution for high tensile pipe and tubing typically used in earthmoving and construction equipment. This welding product boasts enhanced strength in both as welded and stress relieved conditions, thanks to its 0.5% Mo content. Additionally, Spoolarc 83 features elevated levels of Manganese and Silicon, delivering excellent wetting capabilities and superior resistance against rust and scale. This versatile welding solution is suitable for all-position welding and is available in forms compatible with MIG and TIG welding techniques.

| Additional Information |

|---|

| Packaging Description:20 kg spool |

| Weld Process:MIG |

| Grade:ER80S-D2 |

| Diameter:0.045 |

| Packaging:20kg spool, 44lb spool |

| Brand:Esab |

| AWS Spec :ER90S-D2, ER80S-D2 |

| Polarity:DC+ |

| Material Composition:Low Alloy Steel (Manganese-Molybdenum) |

| Wire Type:Solid |

| Shielding Gas Requirement:100% CO2, Argon/CO2 Mix |

| Tensile Strength:90,000 psi min |

| Applications:Heavy Equipment, High Strength Low Alloy Steels |