Package Price:

$148.30/10lb tubeUsually ships within 3-5 business days

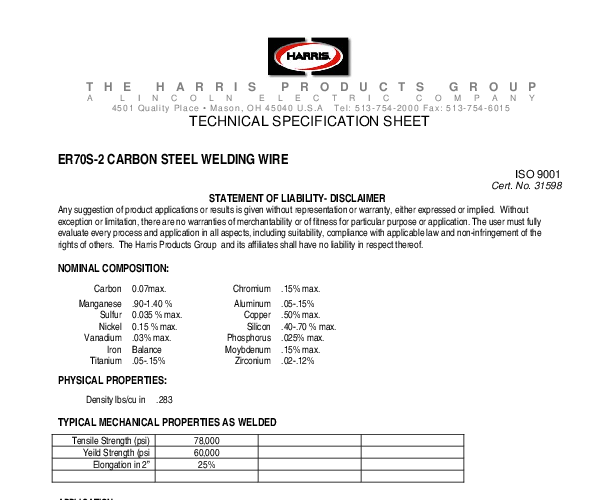

The Harris ER70S-2 Mild Steel TIG Rod is a premium carbon steel filler metal designed for the most demanding industrial applications. Distinguished by its "triple deoxidized" chemistry, this rod contains specific additions of Zirconium, Titanium, and Aluminum, along with the standard Silicon and Manganese found in other mild steel wires. This unique metallurgical composition makes the ER70S-2 exceptionally capable of suppressing porosity, even when welding over contaminants such as rust, mill scale, oil, or dirt. It is the preferred choice for critical welding operations where base metal preparation cannot be perfect or where the highest integrity of the weld deposit is required.

With a diameter of 3.2mm (approximately 1/8 inch), this rod is well-suited for filling joints in thicker sections of mild and low-alloy steels. It is widely recognized as the industry standard for root pass welding on pipe, particularly in the petrochemical, power generation, and offshore industries. The triple deoxidizers act as powerful scavenging agents, reacting with oxygen and nitrogen in the weld pool to form slag that floats to the surface, leaving behind a clean, sound weld metal that consistently passes X-ray inspection. This reliability is crucial for pressure vessels and structural components subject to strict code requirements.

The Harris ER70S-2 also exhibits excellent wetting characteristics, allowing the molten puddle to flow smoothly into the toes of the weld, reducing the risk of lack of fusion. The rods are copper-coated to prevent oxidation during storage and to ensure consistent electrical conductivity during the welding process. Packaged in a durable 10lb tube, these cut lengths are protected from moisture and physical damage, ensuring they arrive ready for immediate use. For fabricators seeking a versatile, high-performance mild steel TIG rod that offers a wide operating window and superior defect tolerance, the Harris ER70S-2 is the optimal solution.

Key Technical Benefits:

| Additional Information |

|---|

| Packaging Description:10lb tube |

| Weld Process:TIG |

| Grade:S2 |

| Diameter:3.2mm |

| Packaging:10lb tube |

| Brand:Harris |

| AWS Spec :ER70S-2 |

| Polarity:DCEN, n/a |

| Material Composition:Mild Steel (Triple Deoxidized) |

| Rod Type:TIG Cut Length |

| Shielding Gas Requirement:100% Argon |

| Wire Finish:Copper-coated |