Sorry, product has been discontinued by the vendor.

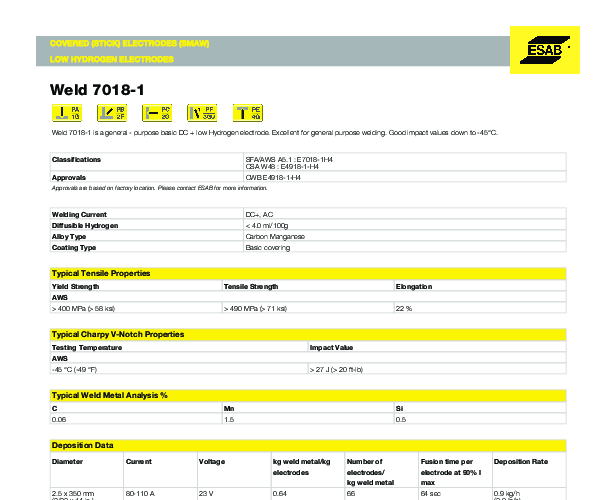

The Stick Electrode Weld 7018-1 5.0 mm (3/16") is a premium quality, low hydrogen, iron powder electrode designed for heavy-duty shielded metal arc welding (SMAW). Engineered to meet the rigorous AWS A5.1 E7018-1 classification, this consumable offers exceptional mechanical properties, specifically high impact toughness at low temperatures (Charpy V-Notch properties at -45°C). This makes it the ideal choice for welding structural steels in bridges, offshore platforms, pressure vessels, and heavy machinery where resistance to brittle fracture is paramount.

The 5.0mm (3/16") diameter is optimized for filling large grooves and creating substantial fillet welds on thick plate sections. The inclusion of iron powder in the coating significantly increases the deposition rate, allowing for faster travel speeds and improved productivity compared to non-iron powder electrodes. Furthermore, the extended 18-inch length is a critical efficiency feature; it allows welders to lay down longer beads before needing to stop and replace the electrode, thereby reducing the number of starts and stops—common points for potential defects.

This electrode is formulated to produce X-ray quality welds with excellent ductility and crack resistance. It operates best on Direct Current Electrode Positive (DCEP), providing deep penetration and reliable fusion. The low hydrogen content (typically under 4ml/100g) is essential for preventing hydrogen-induced cracking (cold cracking) in high-strength carbon and low-alloy steels. Packaged in a robust 6.20 kg tube, these electrodes are protected from moisture absorption, ensuring they remain within specification for critical code work. Proper storage in a holding oven is recommended after opening to maintain low hydrogen status.

| Additional Information |

|---|

| Packaging Description:6.20 kg per pack |

| AWS Spec :E7018-1 |

| Diameter:5.0mm |

| Brand:Esab |

| Polarity:AC/DC-, DC+ |

| Position:ALL, Flat/Horizontal |

| Amp Range:200-300amp |

| Material Composition:Carbon Steel, Iron Powder, Low Hydrogen |

| Length :18 Inches |

| Tensile Strength:70,000 psi (min) |

| Impact Toughness:27J at -45°C |

| Coating Type:Basic, Low Hydrogen |