Package Price:

$104.66/6.2kg per packUsually ships within 3-5 business days

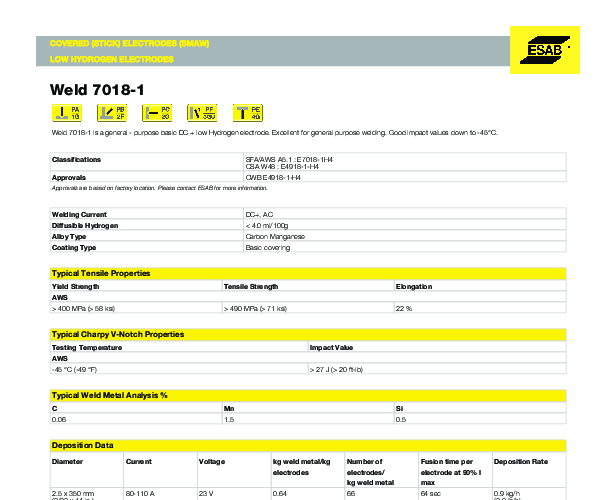

The Bohler E7018-1 Stick Electrode (4.0mm) is a high-performance, basic-coated welding rod designed for the most demanding structural and industrial applications. Engineered to deliver exceptional mechanical properties, this electrode meets the AWS E7018-1 classification, ensuring superior impact toughness even at temperatures as low as -45°C. This makes it the preferred choice for offshore construction, pressure vessel fabrication, and heavy structural steel projects where weld integrity is paramount.

Packaged in a convenient 6.2kg tube, these 18-inch (450mm) electrodes are optimized for efficiency and reduced downtime. The 4.0mm (5/32") diameter allows for higher current carrying capacity and deposition rates, making it ideal for filling larger joints and welding thicker plate sections. The coating is formulated to resist moisture absorption, maintaining low diffusible hydrogen levels (H4 or H8) to prevent cold cracking and ensure X-ray quality welds.

Welders will appreciate the smooth, stable arc and excellent puddle control offered by this electrode. It performs exceptionally well in all positions, including vertical-up, providing a flat to slightly convex bead profile with fine ripples. Slag removal is easy, often self-releasing, which reduces post-weld cleanup time. Whether you are welding fine-grained carbon steels or high-strength low-alloy steels, the Bohler E7018-1 provides the reliability and consistency required for code-compliant work.

| Additional Information |

|---|

| Packaging Description:6-20-kg-per-pack, 6.2kg per pack |

| AWS Spec :E7018-1 |

| Diameter:4-0mm, 4.0mm |

| Brand:Esab, BOHLER |

| Polarity:ac-dc, AC/DC- |

| Position:ALL |

| Amp Range:135-220amp |

| Rod Type:Stick Electrode |

| Coating Type:Basic, Low Hydrogen |

| Current Type:AC, DCEP |

| Tensile Strength:70,000 psi |

| Impact Toughness:-45°C |

| Length :18 Inches, 450mm |