Package Price:

$336.10/18.6kg packIn stock

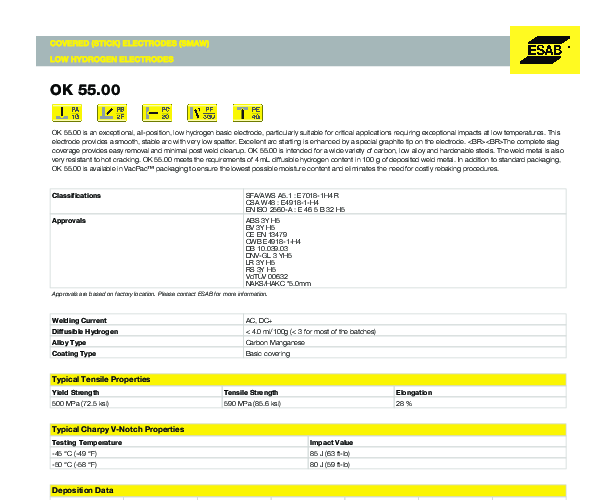

The ESAB OK 55.00 is a high-quality, low-hydrogen stick electrode classified as AWS E7018-1, designed specifically for applications requiring exceptional mechanical properties and radiographic integrity. This 4.0mm (5/32") diameter electrode is engineered to deliver superior crack resistance, particularly when welding high-strength steels, pressure vessels, and shipbuilding grades A, D, and E. The "-1" suffix in the AWS classification denotes its enhanced impact toughness at lower temperatures, making it a preferred choice for projects subject to sub-zero service conditions or dynamic loading.

One of the defining characteristics of the OK 55.00 is its moisture-resistant coating (LMA - Low Moisture Absorption). This feature is critical in preventing hydrogen-induced cracking (cold cracking), a common failure mode in thick-section structural welding. By maintaining low diffusible hydrogen levels, this electrode ensures the long-term durability and safety of the weldment. The chemical composition is carefully balanced to provide a high yield strength of approximately 500 MPa and a tensile strength exceeding 590 MPa, ensuring that the weld metal matches or exceeds the properties of the base material.

The 4.0mm diameter is particularly effective for fill and cap passes on medium-to-heavy plate thicknesses. It offers a deposition rate that balances productivity with heat input control. The electrode operates on both AC and DC+ (Reverse Polarity) currents, providing flexibility for various power sources found in industrial environments. With a metal recovery rate of approximately 120%, the OK 55.00 offers excellent efficiency, depositing more weld metal per electrode compared to standard non-iron-powder types. This product is widely specified in the offshore, energy, and heavy fabrication sectors where quality assurance is paramount.

Storage and handling are simplified due to the robust coating formulation, although standard low-hydrogen practices (rebaking if exposed) should be followed to maintain the H4 hydrogen designation. Whether used for on-site erection of steel structures or shop fabrication of critical components, the ESAB OK 55.00 delivers consistent, code-compliant results that engineers and inspectors trust.

| Additional Information |

|---|

| Packaging Description:18.6kg pack |

| AWS Spec :E7018-1 |

| Diameter:4.0mm |

| Brand:Esab |

| Polarity:AC/DC-, DC+ / AC |

| Position:ALL |

| Amp Range:135-220amp |

| Rod Type:Stick Electrode |

| AWS Classification:E7018-1 |

| Coating Type:Basic, Low Hydrogen |

| Length :18", 450mm |

| Tensile Strength:590 MPa, 85000 psi |

| Yield Strength:500 MPa, 72000 psi |

| Impact Strength:100 J at -40°C |

| Welding Current:AC, DC+ |

| Recovery:120% |