Package Price:

$245.34/14.1kg packIn stock

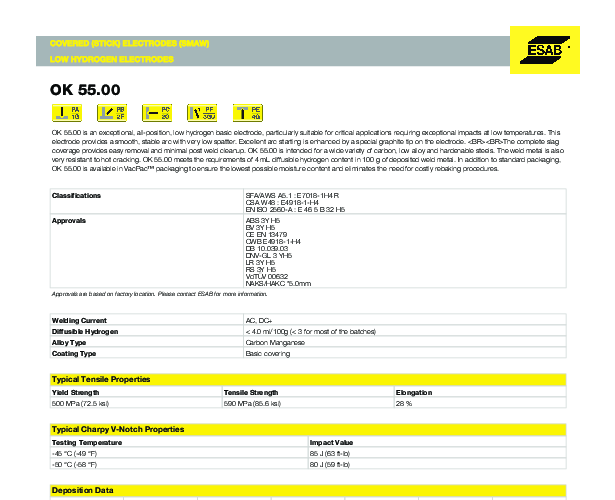

The ESAB OK 55.00 is a premium quality, low-hydrogen manual metal arc (MMA) electrode designed for welding high-strength mild and low-alloy steels. Classified under AWS A5.1 as E7018-1, this electrode is engineered to deliver superior mechanical properties, particularly regarding impact toughness at low temperatures (typically down to -45°C). The '1' suffix in the classification denotes this enhanced impact capability compared to standard E7018 electrodes, making it a critical consumable for industries where structural integrity under thermal stress is paramount.

This 3.2mm (1/8") diameter electrode features a basic coating that provides a metallurgically clean weld deposit with very low hydrogen content. This characteristic is essential for preventing hydrogen-induced cracking (cold cracking) in thick sections or restrained joints. The chemical composition is tightly controlled to ensure consistent performance and high resistance to hot cracking. It is particularly specified for welding high-strength ship steels of grades A, D, and E, as well as for pressure vessels and offshore structures where rigorous quality standards must be met.

The OK 55.00 operates efficiently on both Alternating Current (AC) and Direct Current Electrode Positive (DCEP). Its formulation allows for a stable arc and good bead profile in all welding positions, although it excels in flat and horizontal applications. For procurement and inventory management, this product represents a high-reliability solution for MRO operations dealing with critical infrastructure repairs and fabrication.

| Additional Information |

|---|

| Packaging Description:14.1kg pack |

| AWS Spec :E7018-1 |

| Diameter:3.2mm, 3.2mm (1/8") |

| Brand:Esab |

| Polarity:AC/DC-, DC+, AC |

| Position:ALL |

| Amp Range:100-160amp, 110-150amp |

| Rod Type:Stick Electrode (SMAW) |

| AWS Classification:E7018-1 |

| Coating Type:Basic, Low Hydrogen |

| Welding Position:All position |

| Applications:Pressure Vessels, Shipbuilding, Structural Steel |