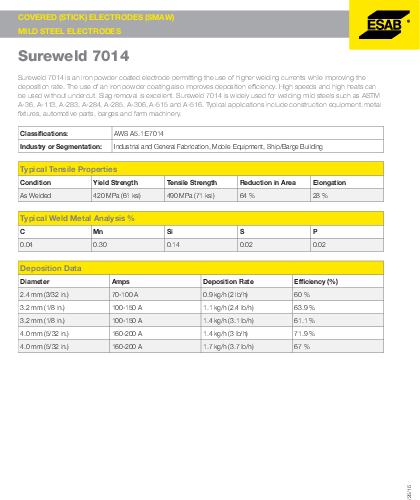

Sureweld 7014 is a reliable iron powder coated electrode that enables the utilization of increased welding currents, resulting in enhanced deposition rates. It effectively prevents undercutting, making it suitable for high-speed and high-heat applications. With excellent slag removal capabilities, Sureweld 7014 is extensively utilized in welding mild steels such as ASTM A-36, A-113, A-283, A-284, A-285, A-306, A-515, and A-516. It finds wide-ranging applications in various industries including construction equipment, metal fixtures, automotive parts, barges, and farm machinery.

| Additional Information |

|---|

| Packaging Description:2.27kg tube |

| AWS Spec :E7014 |

| Diameter:2.5mm |

| Brand:Esab |

| Polarity:AC/DC- |

| Position:ALL |

| Amp Range:100-160amp, 75-110amp |

| Rod Type:Stick Electrode |

| Core Material:Mild Steel |

| Coating Type:Iron Powder Titania |

| Welding Position:All position |

| Current Type:AC, DCEN, DCEP |