Package Price:

$195.63/4.54kg tubeUsually ships within 3-5 business days

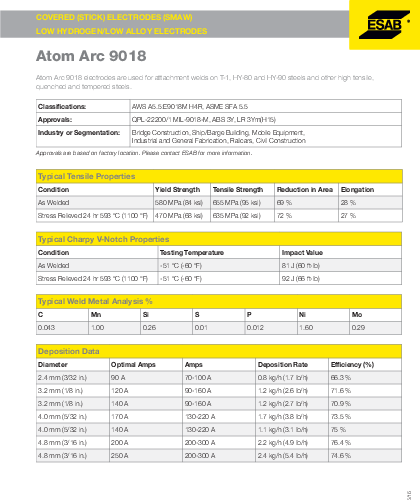

The ESAB 9018-M (2.5mm) is a premium quality, low-hydrogen, iron powder type electrode designed specifically for the welding of high-strength low-alloy (HSLA) steels. Engineered to meet the rigorous AWS E9018-M classification, this consumable delivers a weld deposit with a minimum tensile strength of 90,000 psi, making it an essential choice for structural applications where mechanical integrity and load-bearing capacity are paramount. The electrode features a moisture-resistant coating that significantly reduces the rate of moisture absorption, a critical factor in preventing hydrogen-induced cracking (cold cracking) in high-strength steels. This characteristic ensures that the diffusible hydrogen content remains within safe limits, providing peace of mind for engineers and quality control inspectors involved in critical infrastructure projects.

Metallurgically, the ESAB 9018-M is formulated to provide excellent notch toughness even at lower temperatures, which is vital for structures exposed to harsh environmental conditions or dynamic loading. The 2.5mm diameter is particularly versatile, allowing for precise control in root passes or when welding thinner sections of heavy structures. It operates effectively on both Direct Current Electrode Positive (DCEP) and Alternating Current (AC), offering flexibility depending on the available power source and specific joint configuration. The iron powder addition in the coating improves deposition rates compared to standard low-hydrogen electrodes, enhancing productivity without compromising the mechanical properties of the weld metal.

In industrial environments, reliability is key. This electrode is manufactured under strict quality control standards to ensure consistent burn-off rates, arc stability, and chemical composition. It is widely specified for the fabrication of pressure vessels, penstocks, earthmoving machinery, and offshore structures. The slag system is designed to cover the weld bead completely, protecting it from atmospheric contamination during cooling, yet it detaches easily to minimize post-weld cleaning time. For procurement managers and welding engineers, the ESAB 9018-M represents a balance of high performance, safety compliance, and operational efficiency.

Storage and handling are simplified due to the robust coating formulation, although standard practices for low-hydrogen consumables should still be observed to maintain the H4 or H8 hydrogen designation often associated with premium E9018-M products. Whether used in the shop or the field, this electrode provides the consistent penetration and fusion required to meet code requirements such as AWS D1.1 and ASME Section IX.

| Additional Information |

|---|

| Packaging Description:4.54kg tube |

| AWS Spec :E9018-M |

| Diameter:2-5mm, 2.5mm |

| Brand:Esab |

| Polarity:dc, DC+ / AC |

| Position:ALL |

| Amp Range:75-115amp |

| AWS Classification:E9018-M |

| Rod Type:Stick Electrode |

| Coating Type:Low Hydrogen Iron Powder |

| Tensile Strength:90,000 psi (min) |

| Welding Position:All position |

| Current Type:AC, DCEP |

| Moisture Resistance:High |