Package Price:

$177.00/10lb tubeIn stock

The Central Wire ER316L is a premium quality austenitic stainless steel TIG welding rod designed to meet the rigorous demands of industrial fabrication. Classified under AWS A5.9 as ER316L, this filler metal is engineered for joining Type 316 and 316L stainless steels. The 'L' designation indicates a low carbon content, restricted to a maximum of 0.03%, which is critical for preventing sensitization and intergranular corrosion (carbide precipitation) in the heat-affected zone (HAZ) during the welding process. This feature eliminates the need for post-weld annealing in many applications, preserving the structural integrity and corrosion resistance of the base material.

A defining characteristic of the ER316L alloy is the addition of Molybdenum (2.0% – 3.0%). This alloying element significantly enhances the material's resistance to pitting and crevice corrosion, particularly in environments containing chlorides, such as marine atmospheres or chemical processing plants. Furthermore, Molybdenum improves the alloy's creep strength at elevated temperatures, making it suitable for high-temperature service applications where standard 304/308 grades might fail.

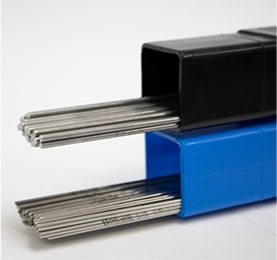

This 1.6mm (1/16 inch) diameter rod is manufactured to precise tolerances to ensure consistent feeding and arc stability. The chemical composition typically includes 18-20% Chromium and 11-14% Nickel, providing a balanced austenitic microstructure with a small amount of ferrite to prevent hot cracking during solidification. The rods are supplied in 36-inch cut lengths, cleaned and packaged in a 10lb protective tube to prevent contamination from moisture, oil, or shop dust. Traceability is maintained through lot numbers, ensuring compliance with ISO and AWS quality management standards.

Technical Specifications:

| Additional Information |

|---|

| Packaging Description:10lb tube |

| Weld Process:TIG |

| AWS Spec :ER316L |

| Packaging:10lb tube |

| Grade:316 |

| Diameter:1.6mm |

| Polarity:DC-, DC+ |

| Brand:Central Wire |

| Material Composition:Molybdenum Bearing, Stainless Steel 316L |

| Rod Length:36 inches |

| Shielding Gas Requirement:100% Argon |

| AWS Classification:AWS A5.9, ER316L |

| Welding Position:All position |