Description:

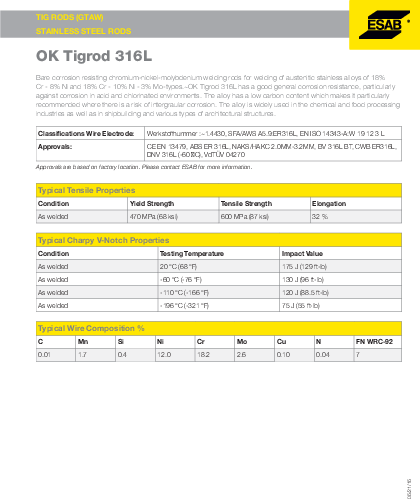

Enhance the performance of your welding projects with our bare corrosion resisting welding rods. Specifically designed for welding austenitic stainless alloys, these rods are perfect for alloys containing 18% chromium and 8% nickel or 18% chromium, 10% nickel, and 3% molybdenum.

Our OK Tigrod 316L provides exceptional resistance against general corrosion, especially in acidic and chlorinated environments. With a low carbon content, this alloy is highly recommended for preventing intergranular corrosion. It is widely utilized in the chemical and food processing industries, shipbuilding, and various architectural applications. Upgrade your welding capabilities and achieve remarkable results with our high-quality welding rods.

| Additional Information |

|---|

| Packaging Description:5kg per tube |

| Weld Process:TIG |

| AWS Spec :ER316L |

| Packaging:10lb tube, 5kg tube |

| Grade:316 |

| Diameter:4.0mm |

| Polarity:DC+, DCEN |

| Brand:Esab |

| Material Composition:Stainless Steel |

| Wire Diameter:4.0mm |

| AWS Classification:ER316L |

| Shielding Gas Requirement:Argon |

| Wire Type:Solid |