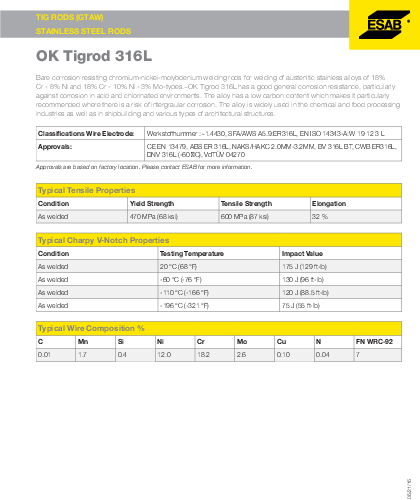

These bare chromium-nickel-molybdenum welding rods are designed for welding austenitic stainless alloys with 18% chromium and 8% or 10% nickel, as well as 3% molybdenum types. OK Tigrod 316L offers excellent general corrosion resistance, especially in acid and chlorinated environments. The alloy's low carbon content makes it highly suitable for applications where intergranular corrosion is a concern. Its versatility has led to its widespread use in industries such as chemical processing, food production, shipbuilding, and architectural construction.

| Additional Information |

|---|

| Packaging Description:5kg tube |

| Weld Process:TIG |

| AWS Spec :ER316L |

| Packaging:5kg tube |

| Grade:316 |

| Diameter:3.2mm |

| Polarity:DC+ |

| Brand:Esab |

| Material:Stainless Steel |

| Length :1000mm, 39" |

| Tensile Strength:600 MPa |

| Country of Origin:Czechia |

| Shielding Gas:100% Argon |

| Alloy Type:Austenitic Stainless Steel |