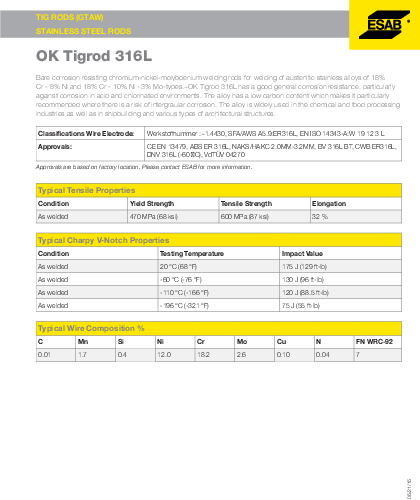

These bare welding rods are designed to resist corrosion, made with chromium, nickel, and molybdenum. Specifically created for welding austenitic stainless alloys containing 18% chromium and 8% nickel or 18% chromium, 10% nickel, and 3% molybdenum. OK Tigrod 316L offers excellent overall corrosion resistance, especially against acid and chlorinated environments. With a low carbon content, it is highly recommended in situations where there is a risk of intergranular corrosion. This alloy is widely utilized in industries such as chemical processing, food processing, shipbuilding, and various architectural structures.

| Additional Information |

|---|

| Packaging Description:5kg tube |

| Weld Process:TIG |

| AWS Spec :ER316L |

| Packaging:10lb tube, 5kg-tube |

| Grade:316 |

| Diameter:2-5mm, 2.5mm |

| Polarity:dc, DC+ |

| Brand:Esab |

| Material Composition:Stainless Steel 316L |

| Rod Length:1000mm |

| Shielding Gas Requirement:100% Argon |

| Alloy Type:Austenitic CrNiMo |

| Ferrite Content:FN 3-10 |