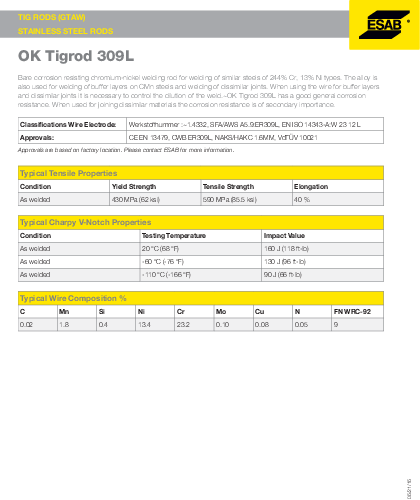

This corrosion-resistant chromium-nickel welding rod is designed for welding similar steels with 24% chromium and 13% nickel composition. It can also be used for creating buffer layers on CMn steels and welding dissimilar joints. Careful control of weld dilution is necessary when utilizing this wire for buffer layers and dissimilar joints. OK Tigrod 309L offers reliable general corrosion resistance. However, its corrosion resistance is of secondary importance when used for joining different materials.

| Additional Information |

|---|

| Packaging Description:5kg tube |

| Weld Process:TIG |

| AWS Spec :ER309L |

| Packaging:10lb tube, 5kg tube |

| Grade:309 |

| Diameter:3.2mm |

| Polarity:DC+ |

| Brand:Esab |

| Material Composition:Stainless Steel |

| Alloy Type:Austenitic Cr-Ni |

| Shielding Gas:100% Argon |

| Current Type:DC(-) |

| Rod Length:1000mm |

| Ferrite Content:FN 3-10 |