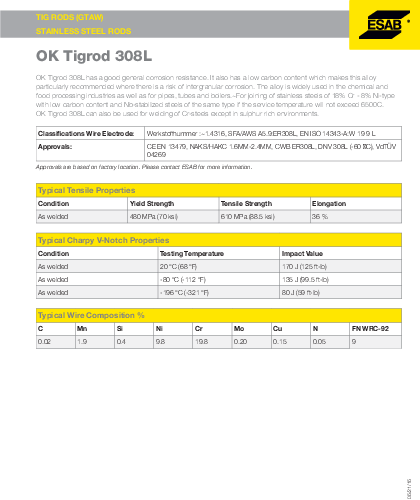

OK Tigrod 308L is a highly reliable alloy with excellent resistance to general corrosion. Its low carbon composition makes it ideal for applications that are susceptible to intergranular corrosion. This versatile alloy is widely utilized in various industries including chemical and food processing. It is also highly recommended for joining stainless steels with low carbon content and Nb-stabilized steels of the same type, as long as the operating temperature does not exceed 350°C. Additionally, it can be employed for welding Cr-steels, except in environments with high sulphur levels.

| Additional Information |

|---|

| Packaging Description:5kg tube |

| Weld Process:TIG |

| AWS Spec :ER308L |

| Packaging:10lb tube, 5kg tube |

| Grade:308 |

| Diameter:2.5mm |

| Polarity:DC+, DCEN |

| Brand:Esab |

| Material Composition:Stainless Steel |

| Shielding Gas Requirement:100% Argon |

| Alloy Type:Austenitic Stainless Steel |

| Current Type:DC- |

| Corrosion Resistance:High |