Package Price:

$156.74/1.6 kg tubeIn stock

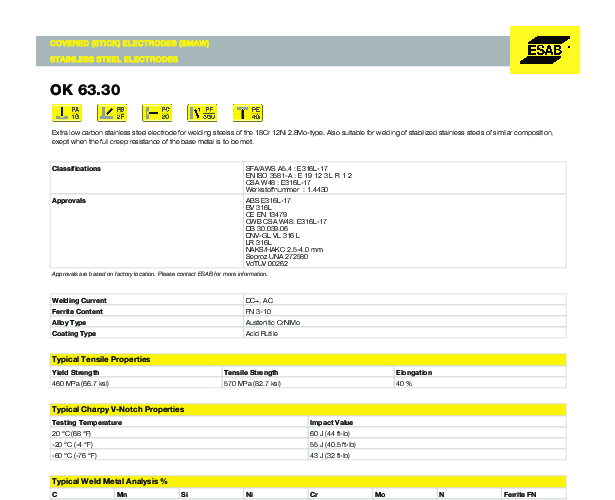

The ESAB OK 63.30 is a high-quality L-grade stainless steel stick electrode designed for the Shielded Metal Arc Welding (SMAW) of austenitic stainless steels of the 18% Cr / 12% Ni / 2.8% Mo type. Classified as an AWS E316L-17, this electrode features an extra low carbon content, which significantly reduces the risk of carbide precipitation and intergranular corrosion, making it suitable for severe corrosive environments.

This 1.6mm diameter variant is specifically engineered for welding thin gauge materials where heat input control is critical. The rutile-acid coating provides a very smooth arc, fine spray transfer, and a flat to slightly concave bead profile. It is particularly effective for applications in the chemical, petrochemical, and food processing industries where 316 and 316L stainless steels are standard. The electrode also offers good resistance to pitting corrosion due to its molybdenum content.

The OK 63.30 is versatile enough to weld stabilized stainless steels of similar composition, such as 316Ti, provided the working temperature does not exceed 350-400°C. Its formulation ensures easy ignition and re-ignition, and the slag is often self-releasing, reducing post-weld cleaning time and labor costs.

| Additional Information |

|---|

| Packaging Description:1.6 kg tube |

| Weld Process:Stick |

| AWS Spec :E316L-17 |

| Packaging:10lb tube |

| Grade:316 |

| Diameter:1.6mm, 2.5mm |

| Polarity:AC or DC+ |

| Brand:Esab |

| Coating Type:Rutile-Acid |

| Material Composition:Stainless Steel |

| Alloy Type:Austenitic CrNiMo |

| Welding Position:All Positions |

| Ferrite Content:FN 3-10 |