Package Price:

$95.73/1.6 kg tubeIn stock

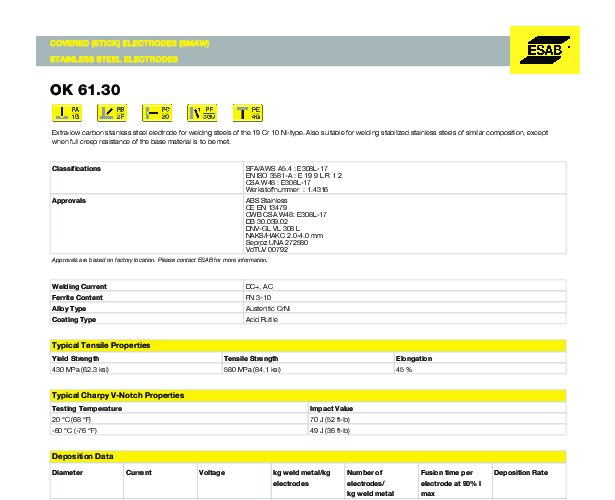

The ESAB OK 61.30 is a high-quality, extra-low carbon (ELC) stainless steel stick electrode classified as E308L-17. Designed specifically for the Shielded Metal Arc Welding (SMAW) process, this electrode is engineered to weld austenitic chromium-nickel steels of the 19Cr-9Ni type, such as AISI 304 and 304L. The 2.5mm diameter makes it versatile for joining thin-to-medium gauge materials where heat input control is critical to maintaining corrosion resistance and mechanical integrity.

One of the defining technical characteristics of the OK 61.30 is its rutile-acid coating. This formulation provides a smooth, stable arc that operates effectively on both Alternating Current (AC) and Direct Current Electrode Positive (DCEP). The coating composition ensures that the molten pool wets out smoothly, resulting in a flat to slightly concave bead profile with fine ripples. This aesthetic finish reduces the need for extensive post-weld grinding and polishing, which is often a significant cost factor in stainless steel fabrication.

Metallurgically, the "L" in E308L indicates a maximum carbon content of 0.04% (often lower in practice with ESAB's quality control), which significantly reduces the risk of carbide precipitation at the grain boundaries. This feature renders the weld metal highly resistant to intergranular corrosion, making it suitable for applications in humid environments or where the material is exposed to mild corrosive agents. The electrode also provides good resistance to general corrosion and is suitable for welding stabilized stainless steels of similar composition when the working temperature is kept below 350°C.

Industrial professionals rely on the ESAB OK 61.30 for its consistency. Whether used in the chemical, food processing, or architectural sectors, this electrode delivers reliable mechanical properties and excellent radiographic quality. Its ability to strike and restrike easily makes it a preferred choice for tack welding and short-run production where stop-start frequency is high.

| Additional Information |

|---|

| Packaging Description:1.6 kg tube |

| Weld Process:Stick |

| AWS Spec :E308L-17 |

| Packaging:10lb tube |

| Grade:308 |

| Diameter:2-5mm, 2.5mm |

| Polarity:AC or DC+, ac-or-dc |

| Brand:Esab |

| Rod Type:Stick Electrode |

| AWS Classification:E308L-17 |

| Coating Type:Rutile-Acid |

| Material Composition:Stainless Steel |

| Welding Position:All positions except vertical down |

| Current Type:AC, DC+ |

| Alloy Type:Austenitic CrNi |