Package Price:

$134.51/1.6 kg tubeUsually ships within 3-5 business days

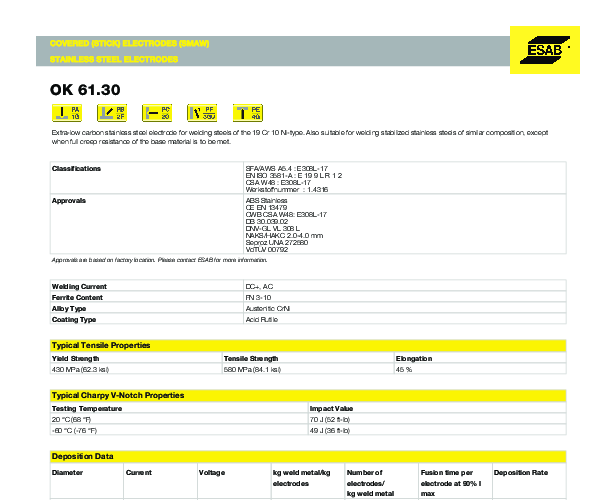

The ESAB OK 61.30 is a high-quality, extra-low carbon (ELC) stainless steel stick electrode classified as E308L-17. Engineered for the Shielded Metal Arc Welding (SMAW) process, this electrode features a rutile-acid coating that delivers exceptional arc stability and weld bead aesthetics. The 1.6mm diameter is specifically suited for welding thin gauge materials where heat input control is critical to prevent burn-through and distortion.

Designed primarily for welding austenitic stainless steels of the 19% Chromium, 10% Nickel type (AISI 304, 304L), the OK 61.30 ensures robust mechanical properties and excellent corrosion resistance. The low carbon content significantly reduces the risk of carbide precipitation and intergranular corrosion, making it a reliable choice for environments subject to wet corrosion. Additionally, it can be used to weld stabilized stainless steels like AISI 321 and 347, provided the service temperature does not exceed 350°C.

Welders appreciate the OK 61.30 for its user-friendly characteristics, including easy ignition and re-ignition, minimal spatter, and self-releasing slag. These features reduce post-weld cleaning time and improve overall productivity. The electrode operates smoothly on both AC and DC+ polarity, offering versatility across various power sources and welding positions. Whether for industrial fabrication in the food and chemical sectors or precision repair work, the ESAB OK 61.30 delivers consistent, high-quality results.

| Additional Information |

|---|

| Packaging Description:1.6 kg tube |

| Weld Process:Stick |

| AWS Spec :E308L-17 |

| Packaging:10lb tube |

| Grade:308 |

| Diameter:1.6mm |

| Polarity:AC or DC+ |

| Brand:Esab |

| Rod Type:Stick |

| AWS Classification:E308L-17 |

| Core Material:Stainless Steel |

| Coating Type:Rutile-Acid |

| Welding Position:All position |

| Applications:Chemical Processing, Food Industry, General Fabrication |