Package Price:

$296.50/25lb spoolUsually ships within 3-5 business days

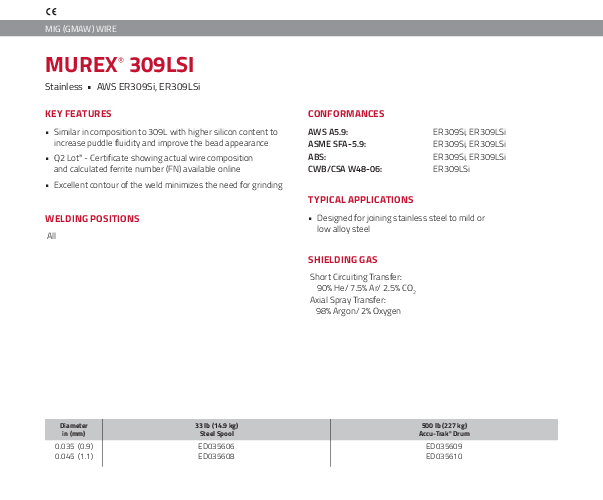

The Murex 309LSi is a premium quality austenitic stainless steel solid wire, specifically engineered for Gas Metal Arc Welding (GMAW). This consumable is classified under AWS A5.9 as ER309LSi. The '309' designation indicates a high chromium (approx. 23-25%) and nickel (approx. 12-14%) content, which provides exceptional oxidation resistance and high-temperature strength. The 'L' denotes a low carbon content (maximum 0.03%), which is critical for preventing carbide precipitation during the welding process, thereby maintaining the corrosion resistance of the grain boundaries in the heat-affected zone (HAZ).

The defining characteristic of this specific alloy is the 'Si' suffix, indicating a higher silicon content (typically 0.65-1.00%) compared to standard 309L grades. This elevated silicon level significantly alters the surface tension of the molten weld pool. Technically, this results in improved wetting action, allowing the puddle to flow more freely towards the toes of the weld. This characteristic is particularly advantageous when welding fillet joints or when a smooth, flat bead profile is required to minimize post-weld grinding. The enhanced fluidity also aids in arc stability and helps to bridge gaps in fit-up, although it requires precise parameter control to prevent sagging in out-of-position welding.

Metallurgically, the Murex 309LSi is designed with a ferrite number (FN) that ensures a duplex microstructure in the deposited weld metal. This ferrite content is essential for preventing hot cracking (solidification cracking), a common issue in fully austenitic stainless steel welds. The alloy is primarily utilized for joining dissimilar metals, such as 304 or 316 stainless steel to carbon or low-alloy steels. It is also the standard choice for depositing buffer layers on carbon steel prior to cladding with 308 or 316 filler metals. The 25lb spool is precision-wound to ensure consistent feedability in automated and semi-automated industrial welding systems.

| Additional Information |

|---|

| Packaging Description:25lb spool |

| Weld Process:MIG |

| AWS Spec :ER309LSI |

| Packaging:25-33lb spool, 25-33lb-spool |

| Grade:309 HISI, 309-hisi |

| Diameter:0-035, 0.035 |

| Polarity:dc, DC+ |

| Brand:Lincoln, Murex |

| Material Composition:Stainless Steel 309LSi |

| Wire Diameter:0.035" |

| Spool Size:25lb |

| AWS Classification:ER309LSi |

| Shielding Gas Requirement:Argon/CO2 Mix, Argon/Oxygen Mix |

| Welding Position:All position |