Description:

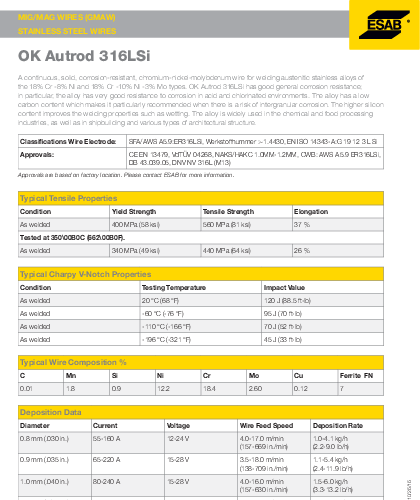

Enhance your welding projects with our exceptional OK Autrod 316LSi wire. Specially designed for welding austenitic stainless alloys, this continuous, solid wire boasts outstanding corrosion resistance due to its chromium-nickel-molybdenum composition. Perfect for 18% Cr -8% Ni and 18% Cr -10% Ni -3% Mo types, it offers remarkable protection against corrosion in acid and chlorinated environments. With its low carbon content, our wire is particularly recommended to prevent intergranular corrosion. Additionally, the higher silicon content elevates its welding properties, ensuring seamless wetting for flawless results. Invest in our reliable and superior quality welding wire for excellent performance and durability.

| Additional Information |

|---|

| Packaging Description:15kg spool, 15kg-spool |

| Weld Process:MIG |

| AWS Spec :ER316LSI |

| Packaging:15kg-spool, 25-33lb spool |

| Grade:316-hisi, 316 HISI |

| Diameter:0-035, 0.035 |

| Polarity:dc, DC+ |

| Brand:Esab |

| Material Composition:Stainless Steel 316LSi |

| Wire Diameter:0.035" |

| AWS Classification:ER316LSi |

| Spool Size:15kg |

| Wire Type:Solid |

| Shielding Gas Requirement:Argon/CO2 Mix, Argon/O2 Mix |

| Welding Position:All position |