Package Price:

$904.35/15kg spoolUsually ships within 3-5 business days

| Additional Information |

|---|

| Packaging Description:15kg spool, 15kg-spool |

| Weld Process:MIG |

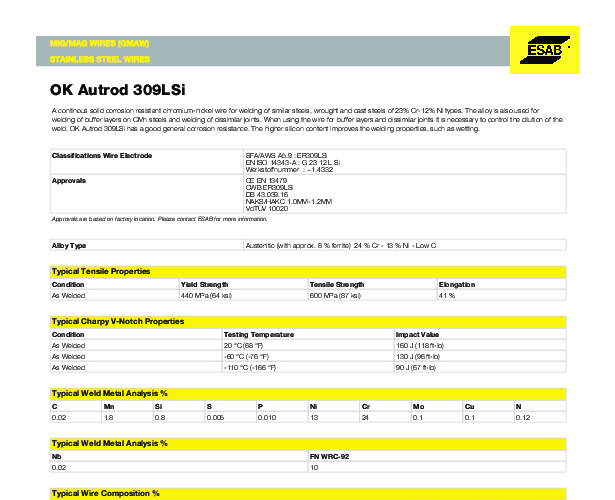

| AWS Spec :ER309LSI |

| Packaging:15kg-spool, 15kg spool |

| Grade:309 HISI, 309-hisi |

| Diameter:0-035, 0.035 |

| Polarity:dc, DC+ |

| Brand:Esab |

| Material Composition:Stainless Steel (309LSi) |

| Wire Diameter:0.035" (0.9mm) |

| Shielding Gas Requirement:Argon/CO2 Mix, Argon/Oxygen Mix |

| Spool Size:15kg (33lb) |

| AWS Classification:ER309LSi |

| Applications:Buffer Layers, Cladding, Dissimilar Metal Joining |

| Alloy Type:Austenitic Stainless Steel |