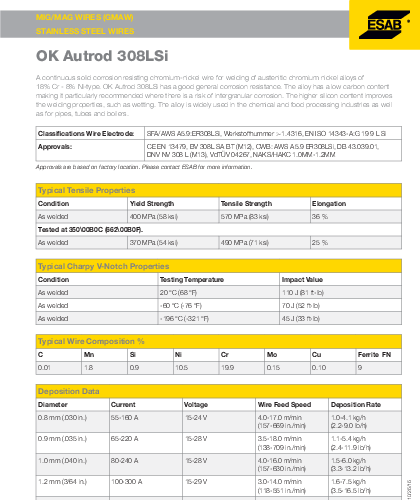

OK Autrod 308LSi is a reliable chromium-nickel wire designed for welding austenitic chromium nickel alloys containing 18% chromium and 8% nickel. This corrosion-resistant wire offers excellent general corrosion resistance. With its low carbon content, it is especially suitable for applications where intergranular corrosion could potentially occur. Furthermore, the increased silicon content enhances the welding characteristics, including improved wetting.

| Additional Information |

|---|

| Packaging Description:15kg spool |

| Weld Process:MIG |

| AWS Spec :ER308LSI |

| Packaging:25-33lb spool, 15kg spool |

| Grade:308 HISI |

| Diameter:0.045 |

| Polarity:DC+ |

| Brand:Esab |

| Material Composition:Austenitic Stainless Steel |

| Wire Type:Solid |

| Shielding Gas Requirement:Argon/CO2 Mix, Argon/Oxygen Mix |

| AWS Classification:ER308LSi |

| Alloy Type:CrNi 18-8 |