Package Price:

$139.80/10lb tubeIn stock

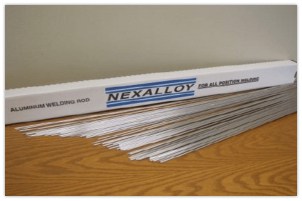

The Nexalloy ER5356 Aluminum TIG Welding Rod is a premium 5% Magnesium alloy filler metal designed for high-strength structural and marine applications. With a diameter of 3.2mm (1/8") and a standard 36-inch length, this 10lb tube provides professional fabricators with a reliable consumable for critical aluminum welding tasks. The 5356 classification is the most widely used aluminum filler alloy next to 4043, but it offers distinct mechanical advantages that make it indispensable for specific industries.

One of the defining characteristics of the Nexalloy 5356 is its resistance to corrosion, particularly in saltwater environments. The addition of magnesium, along with trace amounts of manganese, titanium, and chromium, creates a metallurgical structure that withstands harsh marine conditions far better than silicon-based alloys like 4043. This makes it the filler metal of choice for boat building, ship repair, and offshore structures.

This rod is engineered to weld 5000-series base metals (such as 5050, 5052, 5083, 5154, and 5356) and is also compatible with 6000-series alloys (like 6061 and 6063). While 4043 is often used for 6061, 5356 is preferred when the weldment requires higher shear strength or ductility. The rod produces a deposit with a typical tensile strength of approximately 38,000 psi (265 MPa), ensuring the weld joint is robust enough to handle significant stress loads.

For applications requiring post-weld finishing, Nexalloy 5356 is superior to silicon-based alternatives. When anodized, 5356 welds turn a white color that closely matches the base metal, whereas 4043 welds typically turn dark gray or black, creating an unsightly contrast. This aesthetic advantage makes 5356 the preferred choice for architectural aluminum, bicycle frames, and automotive components where visual consistency is paramount.

| Additional Information |

|---|

| Packaging Description:10lb tube |

| Weld Process:TIG |

| AWS Spec :ER5356 |

| Diameter:3.2mm |

| Packaging:10lb tube |

| Brand:Nexalloy |

| Polarity:DC+ |

| Position:All Position |

| Material Composition:Aluminum-Magnesium (5% Mg) |

| Rod Length:36 inches |

| Shielding Gas Requirement:100% Argon, Argon/Helium Mixtures |

| Tensile Strength:38,000 psi (Typical) |

| Melting Range:1060°F - 1175°F |