Sorry, product has been discontinued by the vendor.

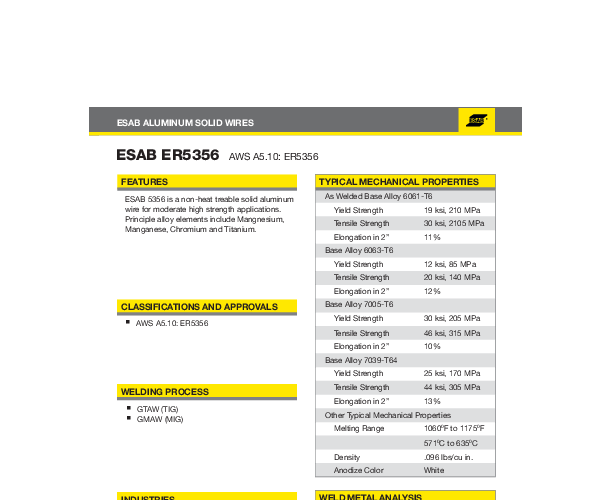

The ESAB OK Tigrod 5356 is a high-quality, general-purpose aluminum welding alloy designed for the Gas Tungsten Arc Welding (GTAW) process. Composed of 5% Magnesium (AlMg5), this filler metal is the industry standard for welding 5000-series aluminum alloys and is widely utilized for its superior mechanical properties. With a diameter of 4.0mm, this specific rod is engineered for heavy-duty applications requiring higher heat input and substantial deposition rates, making it suitable for welding thicker sections of plate and structural components.

One of the primary advantages of the OK Tigrod 5356 is its relatively high shear strength compared to silicon-based alloys like 4043. This makes it the preferred choice for structural applications where mechanical integrity is paramount. The alloy exhibits excellent corrosion resistance, particularly in saltwater environments, which establishes it as a staple in the marine industry for shipbuilding and repair. Furthermore, unlike 4043 which turns dark gray after anodizing, the 5356 alloy maintains a bright, white color match, ensuring an aesthetically pleasing finish on anodized parts.

This filler metal is highly versatile and compatible with a broad range of base materials, including 5050, 5052, 5083, 5356, 5454, and 5456. It is also compatible with 6000-series alloys (such as 6061-T6) and 7000-series alloys where post-weld heat treatment is not required. The 4.0mm diameter provides the welder with the ability to bridge larger gaps and build up welds efficiently on heavy-wall pipes, pressure vessels, and automotive frames. Packaged in a robust 5kg tube, the rods are protected from environmental contaminants, ensuring clean, porosity-free welds every time.

ESAB maintains rigorous quality control standards. The OK Tigrod 5356 meets AWS A5.10 classifications for ER5356, ensuring consistent chemistry and performance. It is approved by major international bodies including CWB, ABS, and VdTÜV, validating its reliability for critical industrial projects.

| Additional Information |

|---|

| Packaging Description:5 kg per tube |

| Weld Process:TIG |

| AWS Spec :ER5356 |

| Diameter:3.2mm, 4.0mm |

| Packaging:10lb tube, 5kg tube |

| Brand:Esab |

| Polarity:AC |

| Position:All Position |

| Material:Aluminum |

| Alloy Type:AlMg5 |

| Tensile Strength:265 MPa (Typical) |

| Elongation:26% (Typical) |

| Shielding Gas:Argon, Argon/Helium Mixtures |

| Approvals:ABS, CWB, DB, VdTÜV |