Sorry, product has been discontinued by the vendor.

The Esab OK Tigrod 5356 is a premium quality aluminum-magnesium alloy TIG welding rod designed for high-performance industrial applications. Classified under AWS A5.10 as ER5356, this filler metal typically contains 5% magnesium, which significantly enhances its mechanical properties compared to standard aluminum-silicon alloys like 4043. The 181532R15A SKU represents a 5kg (approximately 11 lb) tube of 3.2mm (1/8 inch) diameter cut lengths, measuring 39 inches long. This specific diameter is ideal for medium-to-heavy gauge aluminum fabrication where higher deposition rates and robust fusion are required.

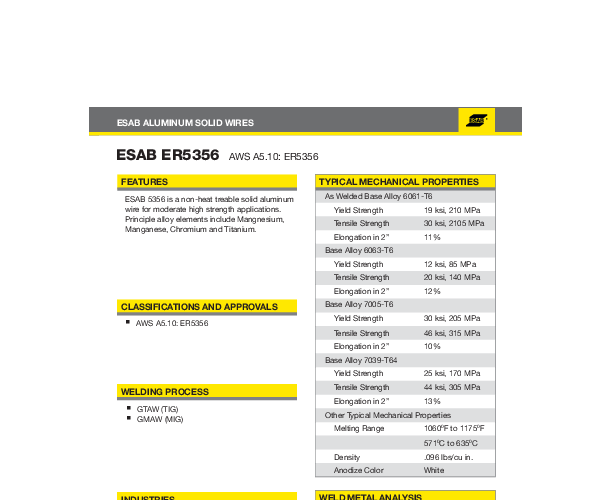

From a metallurgical perspective, the 5356 alloy is non-heat treatable but responds well to work hardening. It exhibits a relatively high shear strength, making it the preferred choice for structural welding applications where the weldment must withstand significant stress. It is compatible with a wide range of base materials, specifically the 5000 series (Al-Mg), 6000 series (Al-Mg-Si), and 7000 series (Al-Zn-Mg) alloys. Notable base metals include 5050, 5052, 5083, 5154, 5356, 6061, and 6063. However, it is important to note that while 5356 has higher strength, it is slightly more prone to stress corrosion cracking at elevated temperatures (above 150°F) compared to other alloys, although it remains the standard for general structural integrity.

One of the defining technical characteristics of the Esab OK Tigrod 5356 is its superior corrosion resistance, particularly in marine environments involving saltwater exposure. This makes it an essential consumable for the shipbuilding and offshore industries. Additionally, for applications requiring post-weld surface finishing, 5356 provides an excellent color match when anodized, avoiding the dark gray or black discoloration often associated with high-silicon fillers like 4043. The rod is designed to operate with 100% Argon or Argon/Helium shielding gas mixtures, utilizing AC current with high-frequency stabilization for optimal oxide cleaning and bead profile.

| Additional Information |

|---|

| Packaging Description:5kg tube, 5kg tube (5kg-tube) |

| Weld Process:TIG (tig), TIG |

| AWS Spec :ER5356, ER5356 (er5356) |

| Diameter:3.2mm, 3.2mm (3-2mm) |

| Packaging:11lb tube |

| Brand:Esab, Esab (esab) |

| Polarity:AC |

| Position:All Position, All Position (all-position) |

| Material Composition:Aluminum Magnesium Alloy |

| Alloy:5356 |

| Length :39 inches |

| Tensile Strength:39,000 psi (approx) |

| Shielding Gas:100% Argon, Argon/Helium Mixtures |