Package Price:

$243.00/5kg tube20 Still in Stock!

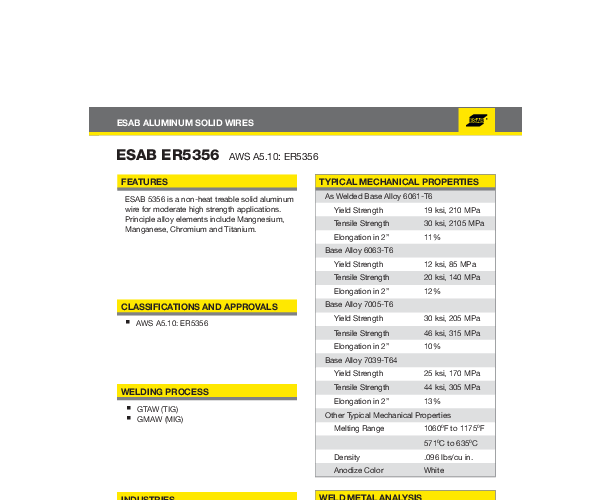

The ESAB OK Tigrod 5356 is a premium quality, general-purpose aluminum welding rod designed for the Gas Tungsten Arc Welding (GTAW) process. Classified under AWS A5.10 as ER5356, this filler metal is an Aluminum-Magnesium (AlMg5) alloy containing approximately 5% magnesium. It is the most widely used welding alloy for structural applications due to its superior mechanical properties relative to the 4000-series filler metals. The 1.6mm diameter offers precision control for thin-to-medium gauge base materials, making it a versatile choice for industrial fabrication.

One of the primary technical advantages of the OK Tigrod 5356 is its relatively high shear strength. Unlike ER4043, which relies on silicon for fluidity, the magnesium content in ER5356 provides a deposit with greater tensile strength and ductility, making it the preferred choice for welding 5000-series base alloys (such as 5083 and 5086) and 6000-series structural alloys (like 6061-T6) when high joint strength is critical. Furthermore, the alloy exhibits excellent resistance to atmospheric and marine corrosion, rendering it indispensable for shipbuilding and offshore applications.

For applications requiring post-weld surface treatment, ESAB OK Tigrod 5356 offers a distinct advantage in anodizing. While silicon-based rods turn dark grey or black after anodizing, the 5356 alloy maintains a color very close to the base metal, ensuring an aesthetically pleasing finish. The manufacturing process of ESAB ensures a clean, oxide-free surface on the rod, promoting consistent electrical conductivity and reducing the risk of porosity in the weld pool. This 5kg tube packaging ensures a substantial supply for production environments while protecting the filler metal from contamination.

| Additional Information |

|---|

| Packaging Description:5kg tube |

| Weld Process:TIG |

| AWS Spec :ER5356 |

| Diameter:1.6mm |

| Packaging:10lb tube |

| Brand:Esab |

| Polarity:AC |

| Position:All Position |

| Material Composition:Aluminum Magnesium Alloy |

| Alloy:5356 |

| Shielding Gas Requirement:100% Argon, Argon/Helium Mixtures |

| Tensile Strength:265 MPa (Typical) |

| Approvals:ABS, CWB, DB, TÜV |