Sorry, product has been discontinued by the vendor.

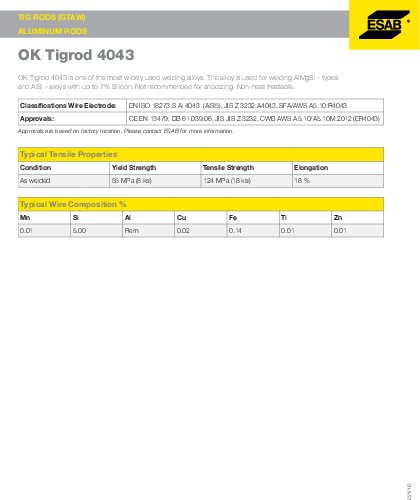

The ESAB OK Tigrod 4043 is a high-quality aluminum TIG welding rod designed for general-purpose fabrication and repair. Classified as AWS A5.10 ER4043, this filler metal is an aluminum alloy containing approximately 5% silicon. The addition of silicon significantly lowers the melting point of the rod relative to the base metal, providing a wider solidification range. This metallurgical characteristic makes the 4043 alloy exceptionally fluid, allowing for excellent wetting action and a smooth, flat bead profile that requires minimal post-weld grinding.

One of the primary technical advantages of the ESAB OK Tigrod 4043 is its ability to minimize hot cracking, particularly when welding heat-treatable base alloys such as the 6000 series (e.g., 6061-T6). The silicon content helps to relieve solidification stresses, making it a safer choice for rigid structures or complex joint configurations where cracking is a concern. This 3.2mm (1/8") diameter rod is specifically sized for welding medium-to-thick sections of aluminum, providing sufficient deposition rates for structural components, automotive parts, and industrial machinery.

While ER4043 is not recommended for parts that will be anodized after welding (as the weld area will turn dark gray), it is the preferred choice for applications requiring pressure tightness and leak resistance due to its superior flow characteristics. It is compatible with a wide range of base materials, including 3003, 3004, 5052, 6061, 6063, and cast aluminum alloys like 43, 355, 356, and 214. Supplied in a robust 5kg tube, these 39-inch (1000mm) cut lengths ensure consistent feeding and handling for professional GTAW operations.

| Additional Information |

|---|

| Packaging Description:5kg tube |

| Weld Process:TIG |

| AWS Spec :ER4043 |

| Diameter:3.2mm |

| Packaging:10lb tube |

| Brand:Esab |

| Polarity:AC |

| Position:All Position |

| Material Composition:Aluminum with 5% Silicon |

| Rod Length:39 inches (1000mm) |

| Alloy Type:4043 |

| Shielding Gas Requirement:100% Argon, Argon/Helium Mixtures |

| Tensile Strength:29,000 psi (typical) |