Sorry, product has been discontinued by the vendor.

| Additional Information |

|---|

| Packaging Description:9-07kg-spool, 9.07kg spool |

| Weld Process:MIG |

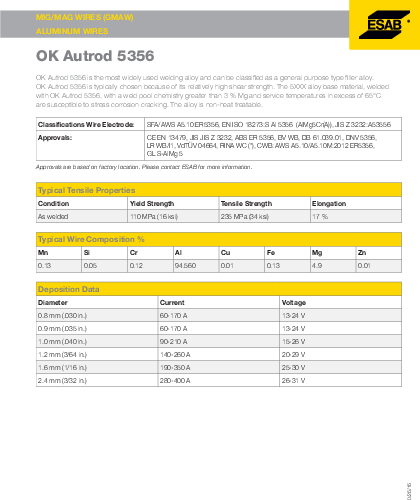

| AWS Spec :ER5356 |

| Diameter:0-045, 0.045 |

| Packaging:20lb-spool, 20lb spool |

| Brand:Esab |

| Polarity:dc, DC+ |

| Position:All Position, all-position |

| Material Composition:Aluminum (AlMg5) |

| Wire Diameter:0.045" |

| Spool Size:20lb (9.07kg) |

| Shielding Gas Requirement:100% Argon, Argon/Helium Mixtures |

| Alloy Type:5356 |

| Tensile Strength:275 MPa (Typical) |