Sorry, product has been discontinued by the vendor.

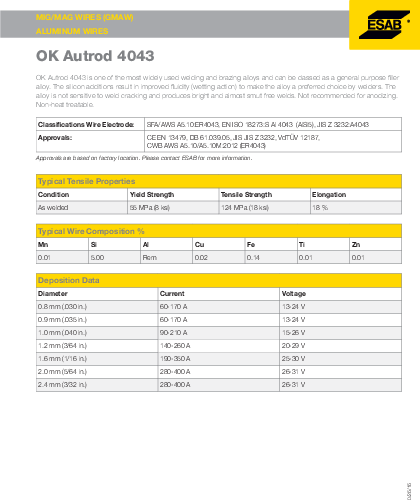

The ESAB OK Autrod 4043 is a high-quality aluminum-silicon alloy MIG welding wire designed for general-purpose welding of aluminum alloys. Classified as ER4043 under AWS standards, this wire contains approximately 5% silicon, which significantly lowers the melting point of the filler metal. This characteristic makes it an exceptional choice for welding heat-treatable base alloys, specifically those in the 6XXX series (such as 6061), as well as 3XXX and 5XXX series alloys. The addition of silicon improves the fluidity of the weld pool (wetting action), allowing for smoother bead profiles and reducing the risk of hot cracking, a common issue in aluminum welding.

One of the defining features of the ESAB OK Autrod series is its manufacturing precision. ESAB limits the wire diameter variations to just 1/10th of the range allowed by the AWS A5.10 specification. This rigorous quality control ensures that the wire feeds consistently through the liner and contact tip, minimizing arc instability and burn-backs that can disrupt production. For industrial applications where uptime and weld quality are paramount, this level of consistency translates directly to cost savings and higher throughput.

This 9.07 kg (20 lb) spool is designed for industrial wire feeders and provides a substantial amount of material for continuous welding operations. The wire produces a bright, shiny weld finish that often requires little to no post-weld cleaning. While 4043 is not recommended for parts that will be anodized for color matching (as the weld will turn dark gray), it is the preferred alloy for general fabrication, automotive repair, and structural components where high strength and crack resistance are required. It is suitable for use with 100% Argon shielding gas or Argon/Helium mixtures for thicker sections.

| Additional Information |

|---|

| Packaging Description:9.07kg spool |

| Weld Process:MIG |

| AWS Spec :ER4043 |

| Diameter:0.045 |

| Packaging:20lb spool |

| Brand:Esab |

| Polarity:DC+ |

| Position:All Position |

| Material Composition:AlSi5, Aluminum |

| Wire Diameter:0.045" |

| Spool Size:20 lb, 9.07 kg |

| Shielding Gas Requirement:100% Argon, Argon/Helium Mixtures |

| AWS Classification:ER4043 |

| Alloy Type:4043 |