Package Price:

$23.07/0.45kg spool2 Still in Stock!

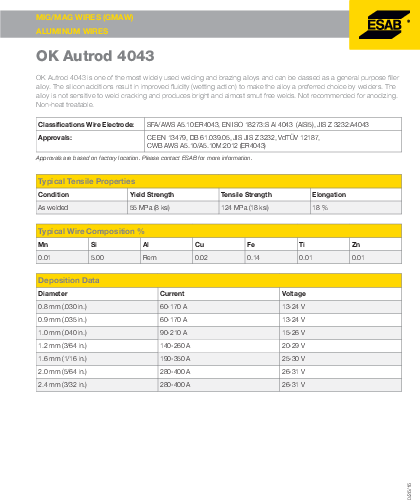

The ESAB OK Autrod 4043 is a high-quality aluminum-silicon alloy welding wire designed for Gas Metal Arc Welding (GMAW). Classified as ER4043 under AWS A5.10 standards, this wire contains approximately 5% silicon, which serves as a critical alloying element. The addition of silicon significantly lowers the melting point of the filler metal relative to the base material, enhancing fluidity and wetting action during the welding process. This characteristic makes OK Autrod 4043 one of the most versatile and widely used aluminum filler metals in the industry, particularly favored for its ability to minimize hot cracking in the weld zone.

This specific product comes in a 0.45kg (1 lb) spool with a wire diameter of 0.045 inches (1.2mm). The smaller spool size is engineered for compatibility with spool guns and compact MIG welding systems, often used for on-site repairs or detailed fabrication work where long cable liners might cause feeding issues with soft aluminum wire. The 0.045-inch diameter is robust enough to handle higher amperage ranges, allowing for spray transfer mode which yields deep penetration and high deposition rates.

Metallurgically, ESAB OK Autrod 4043 is the preferred choice for welding heat-treatable base alloys of the 6xxx series (such as 6061 and 6063) and 3xxx series. While it produces welds with excellent appearance and ductility, it is important to note that 4043 welds are generally not recommended for parts that will be anodized for color matching, as the high silicon content turns the weld dark gray after the anodizing process. However, for general structural applications, automotive components, and industrial repairs, its resistance to solidification cracking makes it superior to 5xxx series fillers in many joint configurations.

ESAB employs rigorous diameter control specifications, limiting wire variations to 1/10 of the standard AWS tolerance. This precision manufacturing ensures consistent electrical contact within the contact tip and smooth feeding performance, reducing downtime caused by burn-backs or bird-nesting.

| Additional Information |

|---|

| Packaging Description:0-45kg-spool, 0.45kg spool |

| Weld Process:MIG |

| AWS Spec :ER4043 |

| Diameter:0-045, 0.045 |

| Packaging:1lb-spool, 1lb spool |

| Brand:Esab |

| Polarity:dc, DC+ |

| Position:All Position, all-position |

| Material Composition:Aluminum Silicon (AlSi5) |

| Wire Diameter:0.045" |

| Spool Weight:0.45 kg (1 lb) |

| Shielding Gas Requirement:100% Argon, Argon/Helium Mixtures |

| AWS Classification:ER4043 |

| Alloy Type:4043 |