Package Price:

$24.17/0.45kg spoolUsually ships within 3-5 business days

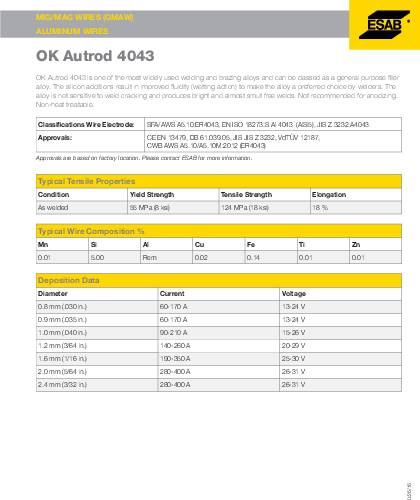

The ESAB OK Autrod 4043 is a high-quality aluminum-silicon alloy welding wire designed for the Gas Metal Arc Welding (GMAW) process. Classified as ER4043, this wire contains approximately 5% silicon, which significantly influences its welding characteristics. The addition of silicon lowers the melting point of the filler metal relative to the base material, providing superior fluidity and wetting action. This makes the 4043 alloy one of the most user-friendly aluminum wires available, particularly for welders seeking a smooth bead profile and excellent tie-in at the toes of the weld.

One of the primary technical advantages of the ESAB 4043 wire is its ability to minimize solidification cracking (hot cracking). This is a critical factor when welding heat-treatable base alloys such as the 6xxx series (e.g., 6061-T6). The wire's chemistry allows for a more forgiving cooling cycle, reducing the internal stresses that lead to centerline cracks. Consequently, it is the preferred choice for general fabrication where high tensile strength is not the sole requirement but where weldability and leak-tightness are paramount.

This specific product comes in a convenient 0.45 kg (1 lb) spool, making it an excellent choice for use with spool guns or smaller portable MIG welders. The 0.035-inch (0.9 mm) diameter is versatile enough for thin-to-medium gauge materials, commonly found in automotive repair, light structural work, and hobbyist projects. ESAB's precision winding ensures that the wire feeds smoothly through the liner and contact tip, reducing the risk of bird-nesting—a common issue with softer aluminum wires. Whether you are repairing a cast aluminum component or fabricating a custom bracket, the ESAB OK Autrod 4043 delivers consistent, high-quality results.

Key Technical Benefits:

| Additional Information |

|---|

| Packaging Description:0-45kg-spool, 0.45kg spool |

| Weld Process:MIG |

| AWS Spec :ER4043 |

| Diameter:0-035, 0.035 |

| Packaging:1lb-spool, 1lb spool |

| Brand:Esab |

| Polarity:dc, DC+ |

| Position:All Position, all-position |

| Material Composition:Aluminum Silicon (AlSi5) |

| Wire Diameter:0.035" |

| Spool Size:1 lb (0.45 kg) |

| AWS Classification:ER4043 |

| Shielding Gas Requirement:100% Argon, Argon/Helium Mixtures |

| Tensile Strength:29,000 psi (typical) |

| Alloy Type:4043 |