In stock

The Western Enterprises FA-230P Flashback Arrestor is a critical safety component designed for professional industrial environments utilizing oxy-fuel cutting and welding processes. Engineered specifically for the fuel gas side of the manifold or cylinder setup, this device mounts directly to the regulator outlet. Its primary function is to mitigate the risks associated with reverse flow and flashbacks, two of the most dangerous phenomena in gas welding. The unit integrates a high-quality internal check valve that automatically prevents the reverse flow of gases, ensuring that oxygen cannot backfeed into the fuel line, which is a common precursor to catastrophic equipment failure.

Beyond simple flow control, the FA-230P features a sintered metal flame barrier that acts as a flashback arrestor. In the event of a flashback—where a flame front travels back up the hose towards the supply—this barrier extinguishes the flame instantly, protecting the regulator, the cylinder, and the operator. The device is constructed from durable brass, ensuring longevity and resistance to the harsh conditions of industrial workshops. It is UL Listed, meeting stringent safety standards required for regulatory compliance in commercial settings.

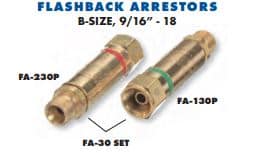

Despite its robust safety features, the FA-230P is designed to maintain high operational efficiency. It boasts a substantial flow capacity, capable of supporting cutting operations on steel up to 10 inches thick. This ensures that safety does not come at the expense of performance. The unit is rated for a maximum operating pressure of 15 PSIG for Acetylene and 22 PSIG for other fuel gases such as Propane or Natural Gas. The connection is a standard "B" size 9/16"-18 Left Hand thread, making it compatible with the vast majority of industrial fuel gas regulators in North America.

Safety officers and procurement specialists should note that the FA-230P provides upstream protection for the gas supply. While torch-mounted arrestors protect the hose, regulator-mounted units like the FA-230P are the final line of defense for the high-pressure cylinders. For comprehensive system safety, industry best practices often recommend the use of arrestors at both the torch and regulator, provided the flow restrictions do not impede the specific application. This unit is strictly for fuel gas service and must not be used on oxygen lines due to the incompatibility of internal materials and thread directions.

| Additional Information |

|---|

| Packaging Description:1 per each |

| Gas Service:Acetylene, Fuel Gas, Natural Gas, Propane |

| Mounting Type:Regulator Mount |

| Connection Thread:9/16"-18 LH, CGA 023 |

| Material:Brass |

| Max Operating Pressure:15 PSIG (Acetylene), 22 PSIG (Other Fuel Gases) |

| Cutting Capacity:Up to 10 inches |

| Certifications:UL Listed |

| Safety Features:Flashback Arrestor, Internal Check Valve |