Usually ships within 3-5 business days

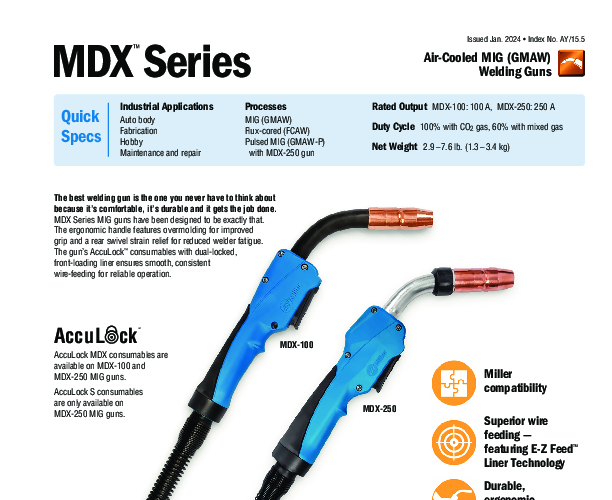

The Miller MDX-250 MIG Gun (1770035) represents the next evolution in welding torch technology, designed to meet the rigorous demands of industrial fabrication and maintenance environments. Engineered as a direct upgrade and replacement for the legacy M-25 guns, the MDX-250 integrates seamlessly with industry-standard equipment including the Millermatic 212 Auto-Set, 252, and 255, as well as the Multimatic 200 and 255 series. This 10-foot air-cooled gun is rated for 250 amps at 100% duty cycle when using CO2 shielding gas, ensuring it can withstand continuous operation in high-volume production settings without overheating.

At the core of the MDX-250's performance is the revolutionary AccuLock™ MDX consumable system. Unlike traditional MIG guns that rely on set screws and manual measurements for liner installation, the AccuLock system features a front-loading liner that locks concentrically at both the front and back of the gun. This dual-locked design eliminates the gap between the liner and the contact tip, ensuring a smooth, uninterrupted path for the welding wire. For industrial operators, this means significantly less downtime caused by burnbacks, birdnests, and erratic arcs. The liner trimming process is error-proof, requiring no measuring, which simplifies training for new welders and guarantees a perfect fit every time a liner is replaced.

Beyond consumables, the MDX-250 is built for versatility. The internal cable construction features increased copper content, making this gun fully capable of handling Pulse Welding (GMAW-P) waveforms. This is critical for modern fabrication shops utilizing advanced processes on materials like stainless steel or thin-gauge aluminum where arc stability is paramount. The gun comes ready to feed .030 to .035 inch wire right out of the box, making it an immediate solution for general steel fabrication tasks. When precision, durability, and ease of maintenance are non-negotiable, the Miller MDX-250 is the professional's choice.

| Additional Information |

|---|

| Packaging Description:1 Per Ea |

| Brand:Miller |

| Amps:250amp |

| Length :10 ft |

| Back End:Miller |

| Wire Size:0.030, 0.035 |

| Cooling Method:Air Cooled |

| Duty Cycle:100% with CO2, 60% with Mixed Gas |

| Consumable Series:AccuLock MDX |

| Handle Type:Ergonomic with Rubber Overmolding |

| Cable Strain Relief:Rear Swivel |

| Process:Flux Cored (FCAW), MIG (GMAW), Pulsed MIG (GMAW-P) |