Usually ships within 3-5 business days

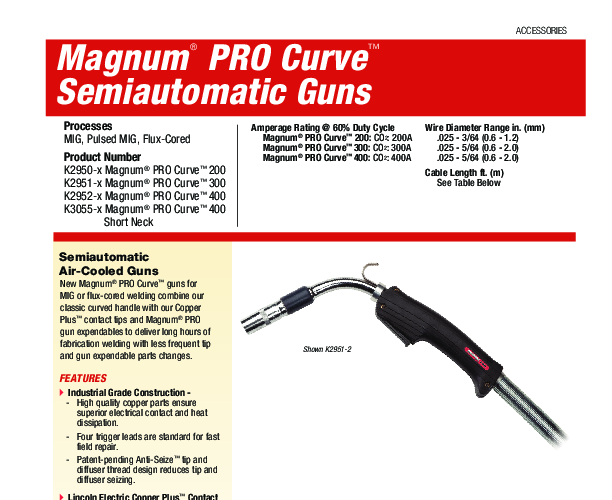

The Lincoln Electric Magnum® PRO Curve™ 300 Welding Gun (K2951-2) is engineered to meet the rigorous demands of industrial fabrication while prioritizing operator comfort. Designed for semiautomatic MIG, Pulsed MIG, and Flux-Cored welding applications, this air-cooled gun delivers a rated output of 300 Amps at 60% duty cycle when using CO2 gas. Its robust construction ensures longevity in tough shop environments, making it a reliable choice for professionals who require consistent performance.

One of the standout features of the Magnum PRO series is the integration of Lincoln Electric's Copper Plus® Contact Tips. These tips are designed with a larger diameter and greater mass compared to standard tips, which significantly improves heat dissipation. This thermal efficiency translates to extended tip life and reduced downtime for consumable changes. Additionally, the patent-pending Anti-Seize tip and diffuser thread design prevents parts from fusing together, ensuring that maintenance is quick and hassle-free.

Welding fatigue is a common challenge in high-production environments. The Curve™ handle design addresses this by offering a lightweight and balanced grip that fits naturally in the hand. The rotating gun tube and included gun hanger clip provide further flexibility, allowing the operator to adjust the gun's position to fit into tight spaces or rest the gun securely when not in use. With a 15-foot cable length, this gun provides ample reach for large assemblies without compromising on wire feedability.

The K2951-2 is compatible with a wide range of wire diameters, from 0.025 inches to 5/64 inches, making it versatile for various material thicknesses. Whether you are welding mild steel, stainless steel, or aluminum (with appropriate liners), the Magnum PRO Curve 300 delivers stable arc performance. The simplified selection of expendable parts means you spend less time managing inventory and more time welding.

| Additional Information |

|---|

| Packaging Description:1 of each |

| Brand:Lincoln, Magnum |

| Amps:300amp |

| Length :15 ft |

| Front End:Magnum |

| Back End:Powermig |

| Wire Size:0.045 |

| Item:Gooseneck |

| Process Type:Flux-Cored, MIG, Pulsed MIG |

| Cooling Method:Air Cooled |

| Duty Cycle:60% @ 200A (Mixed Gas), 60% @ 300A (CO2) |

| Wire Diameter Range:0.025 - 5/64 in. |

| Cable Length:15 ft |