Usually ships within 3-5 business days

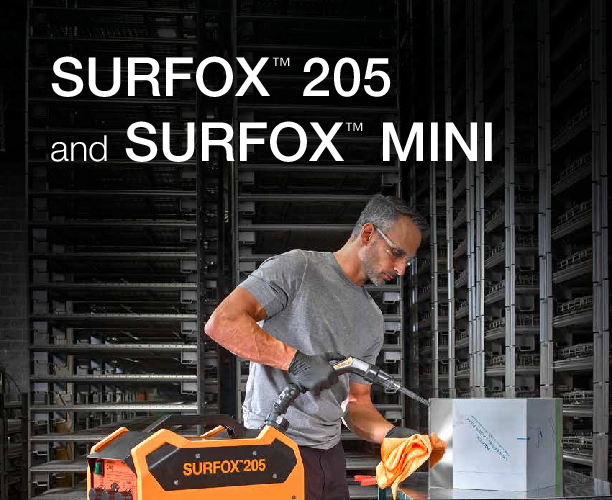

The Walter SURFOX™ 205 is a premier industrial weld cleaning system designed to replace hazardous pickling pastes and labor-intensive mechanical grinding. Engineered for the electrochemical cleaning and passivation of stainless steel TIG and spot welds, this unit restores the chromium oxide layer to the base metal, ensuring corrosion resistance is fully maintained. The system is also capable of cleaning MIG, TIG, and spot welds on aluminum, making it a versatile asset for diverse fabrication environments.

One of the standout features of the SURFOX 205 is its built-in fume elimination system. By connecting a compressed air line, the unit disperses vapors produced during the electrochemical process, significantly improving operator safety and comfort in enclosed spaces. The redesigned pump and tank assembly ensures a consistent flow of electrolyte solution to the workpiece, maximizing fluid efficiency and reducing consumable waste.

The SURFOX 205 offers switchable output modes to handle various surface finishing requirements:

With the addition of specific marking kits (sold separately), the unit can also permanently mark stainless steel, aluminum, and titanium surfaces.

Built for durability, the SURFOX 205 features a Quick-Connect system that allows operators to swap between the standard 4-meter wand and optional 9-meter assemblies in seconds. This starter kit includes everything required to begin operation immediately, including a carbon fiber brush, adaptor, ground cable, and a heavy-duty carrying case for transport and storage.

| Additional Information |

|---|

| Packaging Description:1 of each, 1-per-each |

| Item:Miscellaneous, n/a |

| Brand:Walter |

| Input Voltage:120 V |

| Process Type:Electrochemical Weld Cleaning |

| Output Modes:AC (Cleaning & Marking), DC (Polishing & Etching) |

| Compatible Materials:Aluminum, Stainless Steel, Titanium (Marking only) |

| Wand Length:4 m |