Usually ships within 3-5 business days

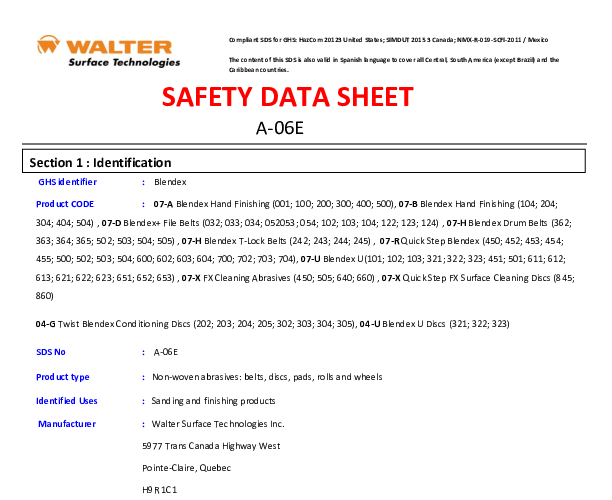

The Walter 07H504 5-3/8" BLENDEX Drum Belt in Fine grade is an essential abrasive tool for industrial metalworking professionals seeking superior surface finishes. Engineered by Walter Surface Technologies, this belt utilizes advanced non-woven technology to deliver a consistent satin finish that enhances the aesthetic quality of metal fabrications. Unlike traditional coated abrasives that may gouge or alter the base material, the BLENDEX material is designed to condition and refine the surface gently, making it the ideal choice for final finishing stages.

This specific belt is rated "Fine," making it perfect for removing minor imperfections, blending handling marks, and creating a uniform grain on stainless steel, steel, and aluminum. The open-web structure of the non-woven material promotes airflow, which significantly reduces heat generation during the finishing process. This is particularly critical when working with heat-sensitive alloys like stainless steel, where discoloration or warping can occur with aggressive grinding. The belt's flexibility allows it to conform to slightly irregular surfaces, ensuring an even finish across the entire workpiece.

Industrial users will appreciate the longevity and cost-efficiency of the 07H504. The high-quality construction resists loading and clogging, extending the operational life of each belt and reducing downtime associated with frequent abrasive changes. Whether used for architectural metalwork, food processing equipment fabrication, or general sheet metal finishing, this drum belt provides the reliability and performance required in high-demand environments. Sold in packs of 10, these belts are compatible with standard linear finishing tools that accept 5-3/8" wide drums, offering a seamless integration into existing finishing workflows.

Key Industrial Benefits:

| Additional Information |

|---|

| Packaging Description:1 per each, 10 per pack |

| Brand:Walter |

| Grit:FINE |

| Width (in):5-3/8" |

| Used to Sand:Steel or Stainless or Aluminum |

| Material:Non-Woven Blendex |

| Product Type:Drum Belt |

| Compatible Tool Type:Drum Sander, Linear Finishing Tool |