Package Price:

$120.00/25 per eachUsually ships within 3-5 business days

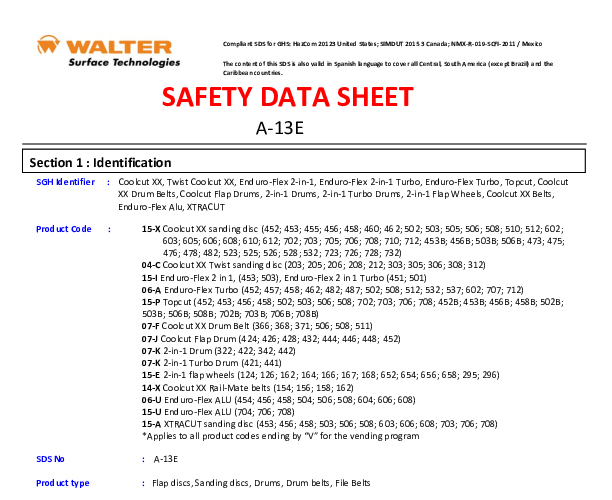

The Walter 15P706 7" Gr60 TOPCUT™ Sanding Disc represents the pinnacle of resin fiber disc technology, engineered specifically for the demanding environments of industrial metal fabrication. Designed to address the common challenges of premature disc wear and thermal damage to substrates, the TOPCUT™ series utilizes a premium Zirconium grain structure. This advanced abrasive material is self-sharpening, ensuring that the disc maintains a high cut rate throughout its entire lifespan rather than dulling rapidly after initial use. For professionals working with stainless steel, heat management is critical; the TOPCUT™ disc features a specialized top coat and a high-strength heat-resistant bond that significantly reduces friction and heat generation. This "cooler sanding" capability is essential for preventing heat tint, warping, and metallurgical changes in the workpiece, thereby reducing the need for costly rework or post-process passivation.

Efficiency in material removal is driven by Walter’s unique electrostatic manufacturing process. This technique orients the abrasive grains vertically, exposing the sharpest cutting edges to the work surface. Combined with the 60-grit specification, this disc offers an optimal balance for medium-to-heavy stock removal tasks, such as leveling welds, breaking edges, and blending surfaces, while still leaving a manageable finish for subsequent steps. The 7-inch diameter format is ideal for covering large surface areas quickly, making it a staple for vessel fabrication, structural steel work, and heavy equipment manufacturing. By integrating durability with aggressive performance, the Walter TOPCUT™ disc reduces downtime associated with frequent disc changes, ultimately lowering total production costs.

Unlike standard aluminum oxide discs that glaze over under high pressure, the Zirconium grain in the 15P706 fractures under stress to reveal new, sharp cutting points. This mechanism allows operators to apply necessary pressure for rapid stock removal without sacrificing the life of the abrasive. The disc is compatible with standard 7-inch angle grinders and requires a suitable backing pad to ensure safety and optimal performance. Whether you are grinding mild steel or finishing high-grade stainless, the TOPCUT™ delivers consistent, professional results.

| Additional Information |

|---|

| Packaging Description:25 per each |

| Brand:Walter |

| Diameter (in):7" |

| Grit:60 |

| Used to Sand:Stainless Steel, Steel |

| Grain Type:Zirconium |

| Disc Type:Resin Fiber Disc |

| Bond Type:Heat Resistant, Resin |

| Application Method:Electrostatic |