Package Price:

$304.00/25 per eachUsually ships within 3-5 business days

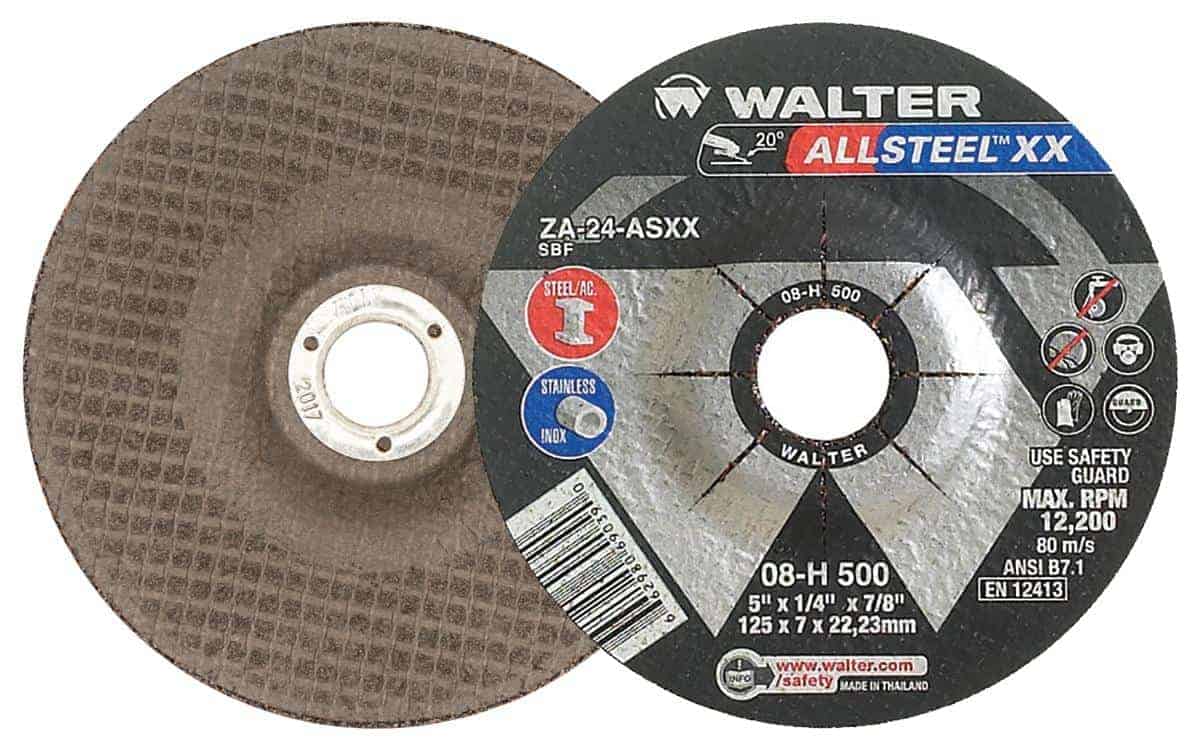

The Walter HP XX™ 5" Grinding Wheel (SKU: 08H500) represents the pinnacle of abrasive innovation tailored for the industrial sector. In high-volume manufacturing and fabrication environments, the cost of consumables is often dwarfed by the cost of labor and downtime. Walter Surface Technologies has engineered the HP XX series to address this specific economic equation. By incorporating the latest advancements in grain chemistry and bonding matrices, this grinding wheel delivers a performance profile that maximizes material removal rates while simultaneously extending the service life of the wheel.

Designed specifically for use on steel, the HP XX utilizes a proprietary formulation that resists glazing and maintains a sharp cutting edge throughout its lifecycle. This ensures that operators can maintain peak productivity without the fatigue associated with inefficient abrasives. For facility managers and procurement specialists, the 08H500 offers a tangible reduction in total grinding expenses. Fewer wheel changes mean less downtime, and faster cutting speeds mean projects move through the production line more rapidly. The 5-inch diameter combined with a 1/4-inch thickness provides a robust platform for heavy stock removal, making it an essential asset for structural steel plants, shipyards, and heavy machinery manufacturing.

Safety and consistency are paramount in industrial MRO. Walter’s manufacturing process guarantees that every HP XX wheel meets rigorous safety standards, providing smooth, vibration-free operation that protects both the tool and the operator. When your operation demands the lowest cost-per-cut and the highest throughput, the Walter HP XX is the strategic choice for your abrasive inventory.

| Additional Information |

|---|

| Packaging Description:25 per each |

| Brand:Walter |

| Diameter (in):5" |

| Thickness (in):1/4" |

| Arbor (in):7/8" |

| Used to Grind:Steel |

| Item:Grinder |

| Product Line:HP XX |

| Application Material:Steel |

| Wheel Type:Type 27 |