Package Price:

$283.50/25 per eachUsually ships within 3-5 business days

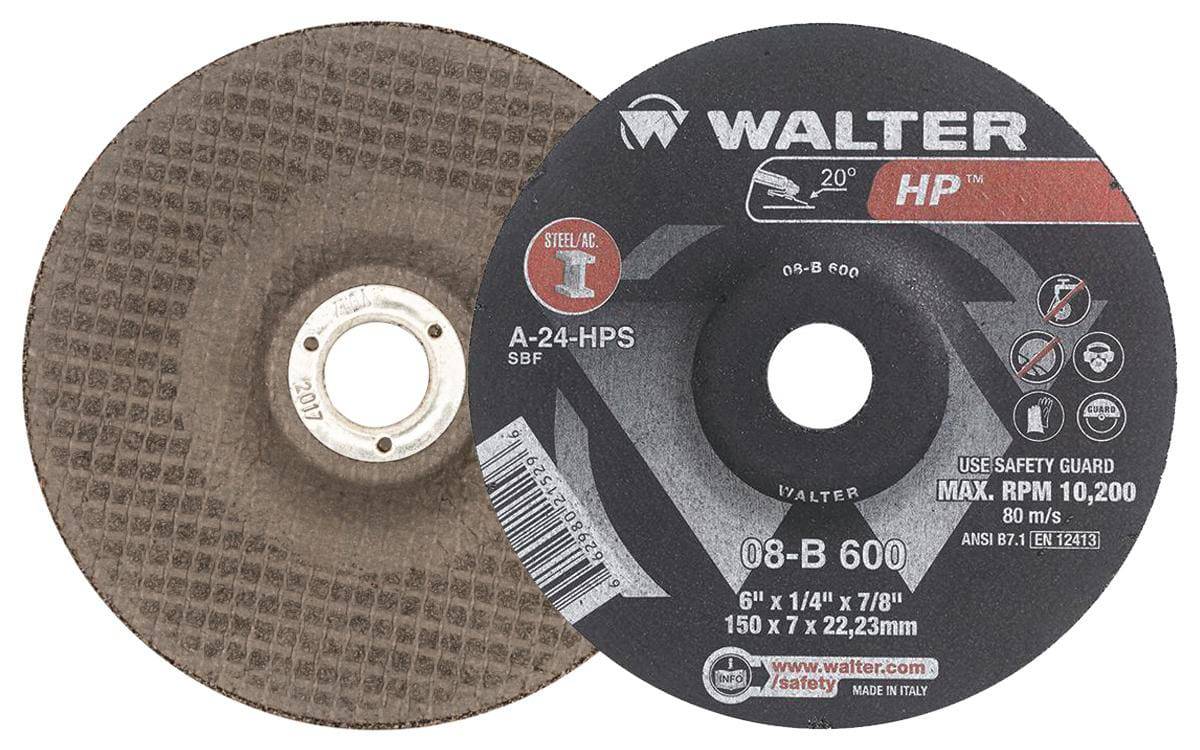

The Walter Allsteel Xtra Grinding Wheel (SKU: 08C600) represents the pinnacle of abrasive technology for heavy-duty industrial applications. Designed to meet the rigorous demands of modern metal fabrication shops, this 6-inch wheel is engineered to deliver exceptional material removal rates while maintaining a long service life. In high-throughput environments where downtime equates to lost revenue, the Allsteel Xtra stands out by reducing the frequency of wheel changes, thereby optimizing operational efficiency.

At the core of this wheel's performance is Walter's proprietary grain blend and state-of-the-art bonding system. This advanced formulation allows the wheel to attack the workpiece aggressively, removing heavy stock from both carbon steel and stainless steel with ease. Unlike standard abrasives that may glaze over or degrade rapidly under high pressure, the Allsteel Xtra maintains its cutting efficacy throughout its lifespan. This consistency is crucial for automated or semi-automated processes as well as manual grinding stations where predictability and speed are paramount.

Safety is a non-negotiable aspect of industrial grinding, and Walter Surface Technologies has integrated robust safety features into the 08C600. The reinforced bonding matrix ensures structural integrity even at the high rotational speeds of 6-inch angle grinders (rated up to 10,200 RPM). This focus on safety, combined with the wheel's superior balance, minimizes vibration and reduces the risk of operator fatigue-related errors. For MRO managers and procurement specialists looking to standardize their abrasive inventory, the Allsteel Xtra offers a versatile solution that covers a wide range of ferrous metal applications without compromise.

Whether utilized for preparing weld seams, beveling heavy plates, or general fabrication tasks, this grinding wheel delivers professional-grade results. Its compatibility with both steel and stainless steel eliminates the need for stocking multiple wheel types for different ferrous materials, streamlining inventory management and ensuring that the right tool is always available for the job.

| Additional Information |

|---|

| Packaging Description:25 per each |

| Brand:Walter |

| Diameter (in):6" |

| Thickness (in):1/4" |

| Arbor (in):7/8" |

| Used to Grind:Steel or Stainless |