Package Price:

$258.40/10 per eachUsually ships within 3-5 business days

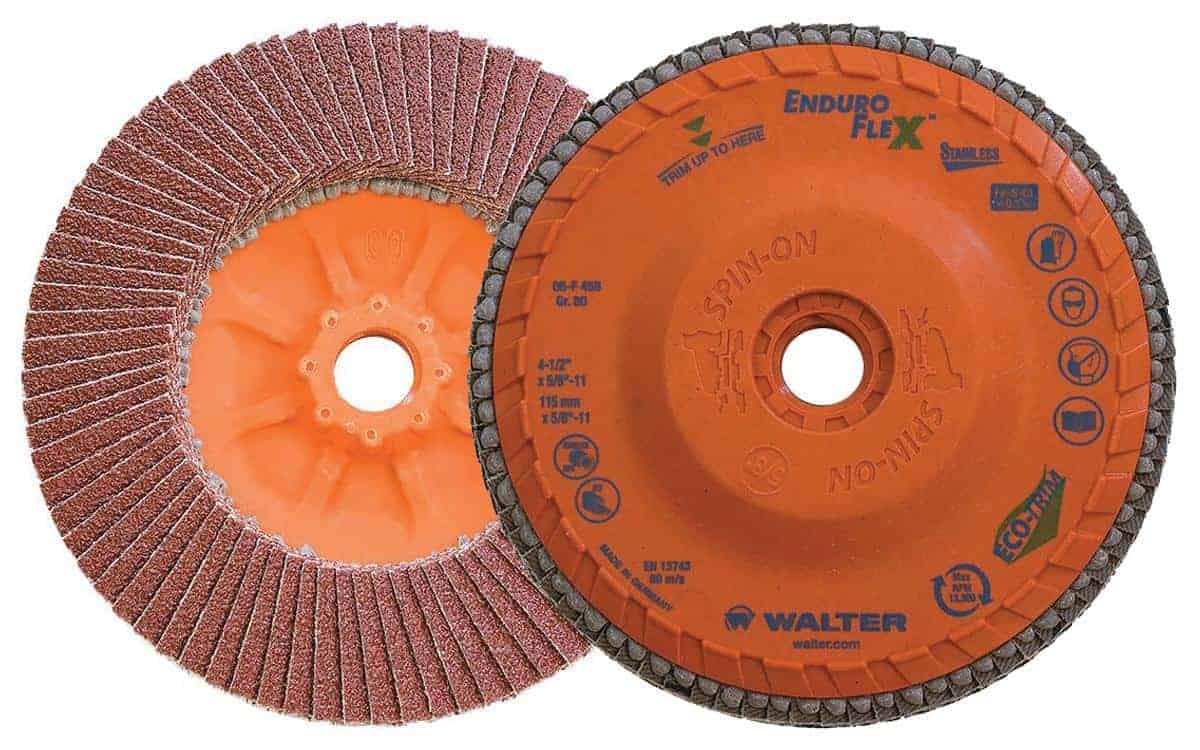

The Walter ENDURO-FLEX Stainless™ (SKU: 06F458) represents a significant advancement in abrasive technology, specifically engineered for the metallurgical demands of stainless steel, aluminum, and copper alloys. This 4-1/2" Grit 80 flap disc distinguishes itself with the proprietary Eco-Trim™ backing, a structural innovation made from natural, sustainable plant fibers. Unlike traditional fiberglass or plastic backings, this material is not only environmentally responsible but also functionally superior in heat dissipation. The porous nature of the plant fibers contributes to a cooler cutting action, which is critical when working with stainless steel to prevent heat-affected zones (HAZ), discoloration, or glazing of the workpiece.

Operational efficiency is maximized through the disc's trimmable design. As the abrasive flaps wear down, the backing can be easily trimmed away, exposing fresh abrasive material that would otherwise be discarded in standard fixed-backing discs. This feature can extend the usable service life of the disc by up to three times, significantly altering the cost-per-grind metric for industrial operations. The Spin-On mounting system incorporates a built-in 5/8"-11 threaded hub, ensuring perfect centering and reducing the dynamic imbalance often associated with locking nuts. This results in a vibration-free operation that protects both the angle grinder's bearings and the operator's musculoskeletal health during prolonged use.

The abrasive composition is tailored for blending and finishing in a single step. The 80-grit configuration provides a balance between material removal and surface finish quality, making it an optimal choice for light weld removal and surface conditioning. The raised hub profile ensures compatibility with standard grinder flanges while providing the necessary clearance for flush grinding applications. By integrating sustainable materials with high-performance abrasive mechanics, Walter Surface Technologies delivers a consumable that meets modern requirements for both productivity and environmental stewardship.

| Additional Information |

|---|

| Packaging Description:10 per each, 10 per each (10-per-each) |

| Brand:Walter (walter) |

| Diameter (in):4.5" (4-5) |

| Grit:80 (80) |

| Used to Grind:Steel or Stainless or Aluminum (steel-or-stainless-or-aluminum) |

| Backing Material:ECO-TRIM Plant Fiber |

| Mounting Type:Spin-On |

| Application Material:Aluminum, Copper Alloys, Stainless Steel |