Usually ships within 3-5 business days

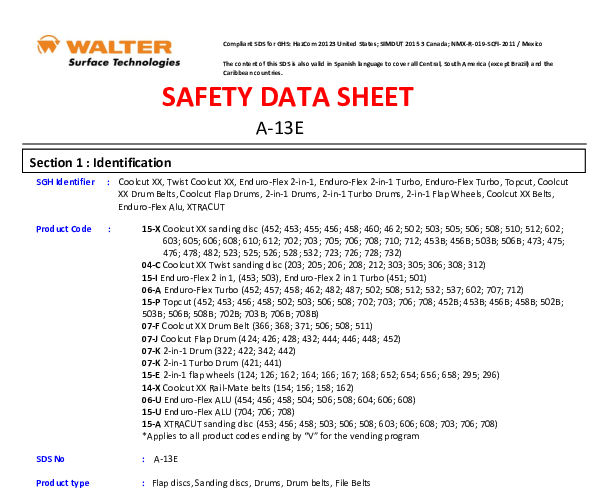

The Walter 07J446 4-1/4" x 4" Flap Drum (Grit 60) is a premium abrasive solution engineered for the rigorous demands of industrial metal finishing. Designed primarily for use with linear finishing tools, such as the Walter Line-Mate system, this flap drum excels at creating uniform, directional grain finishes on a variety of metals. The 60-grit composition makes it an aggressive yet controlled option for the initial phases of the finishing process, capable of removing surface imperfections, light welds, and handling marks while establishing the foundation for a pristine final appearance.

Constructed from top-tier abrasive cloth, this drum is characterized by its durability and resistance to loading. In industrial environments where downtime equates to lost revenue, the glaze-free performance of Walter abrasives ensures continuous operation without the frequent need for changeouts. The flaps are arranged to provide a cushioned touch, allowing the drum to conform slightly to the workpiece, which helps in blending uneven surfaces without gouging or undercutting the base material. This makes it particularly effective for applications involving stainless steel enclosures, food processing equipment, and architectural metalwork where aesthetic consistency is paramount.

Beyond stainless steel, the 07J446 is highly versatile, delivering excellent results on aluminum and mild steel. Its open-coat structure helps dissipate heat, preventing discoloration or warping of heat-sensitive alloys during aggressive grinding sessions. Whether utilized for deburring cut edges, blending weld seams, or restoring a satin finish to scratched surfaces, this flap drum represents the intersection of efficiency and quality. It is an essential consumable for fabrication shops focused on high-value metal production.

| Additional Information |

|---|

| Packaging Description:1 per each |

| Brand:Walter |

| Grit:60 |

| Diameter (in):4-1/4" |

| Width (in):4" |

| Used to Grind:Steel or Stainless or Aluminum |

| Item:Flap Drum |

| Product Type:Coated Abrasive Flap Drum |

| Compatible Tool:Line-Mate III, Linear Finishing Tools |

| Abrasive Material:Premium Abrasive Cloth |

| Application Type:Blending, Deburring, Line Finishing |