Usually ships within 3-5 business days

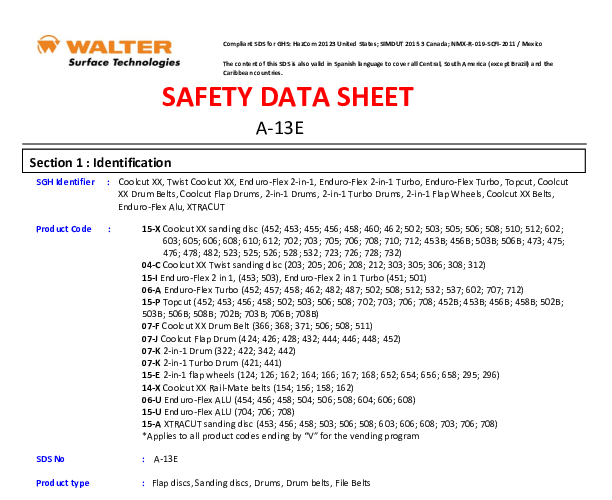

The Walter 15E654 Two-In-One™ Flap Wheel represents a significant leap forward in surface finishing technology for industrial applications. Designed to streamline the metalworking process, this 3-inch by 1-1/2-inch wheel features a unique construction that interleaves high-quality coated abrasive cloth with non-woven conditioning material. This hybrid design allows operators to perform two distinct operations simultaneously: aggressive material removal and fine surface conditioning. By combining the cutting power of a traditional flap wheel with the smoothing capabilities of a non-woven drum, the Two-In-One system effectively removes light defects while leaving a uniform satin finish.

Engineered for precision and longevity, the Fine grit composition is specifically calibrated to address the needs of stainless steel, aluminum, brass, and copper fabrication. In many industrial settings, achieving a food-grade or pharmaceutical-grade finish requires multiple steps—grinding down a weld, sanding out the scratches, and then blending the grain. The 15E654 condenses these stages, allowing for the removal of light TIG welds, surface scratches, and handling marks in a single pass. This not only increases throughput but also reduces the inventory of different abrasive grades required at the workstation.

Thermal management is critical when working with heat-sensitive alloys. The non-woven layers in this wheel provide a cushioning effect and facilitate airflow, ensuring a cool cutting action that minimizes the risk of heat discoloration or warping on thin-gauge metals. The threaded arbor integration ensures a secure, vibration-free connection to power tools, enhancing operator comfort and control during extended use. Whether used for blending corners on a railing or refinishing a tank surface, the Walter Two-In-One wheel delivers consistent, professional results with minimal effort.

This wheel is built to withstand the rigors of daily industrial use. The abrasive flaps self-sharpen as they wear, exposing fresh grain to maintain a consistent cut rate throughout the life of the product. The interleaved non-woven material helps to regulate the depth of the scratch pattern, preventing over-grinding and ensuring a smooth transition between the worked area and the base metal. For MRO professionals and fabricators looking to optimize their finishing workflow, the Walter 15E654 offers an unmatched combination of speed, quality, and durability.

| Additional Information |

|---|

| Packaging Description:1 per each |

| Brand:Walter |

| Diameter (in):3 |

| Width (in):1.5 |

| Grit:FINE |

| Used to Sand:Stainless or Aluminum |

| Product Type:Two-In-One Flap Wheel |

| Construction:Interleaved Sanding Cloth and Non-Woven |

| Mounting Type:Threaded Arbor |

| Application:Blending, Finishing, Light Deburring |