Usually ships within 3-5 business days

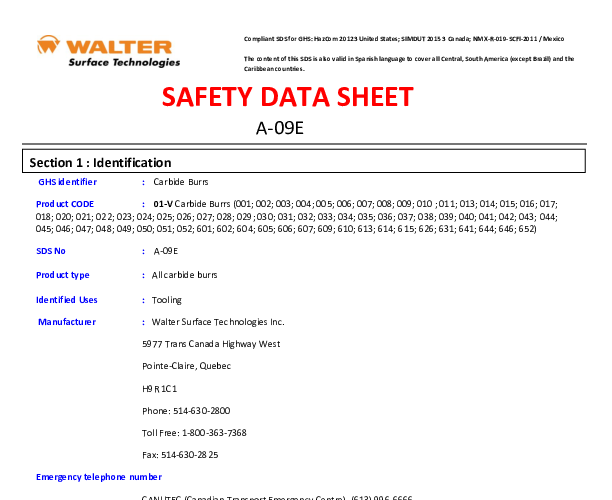

The Walter 01V610 Carbide Burr is an industrial-grade rotary file designed for high-performance metal removal and finishing. Featuring the SD-3 Ball shape, this tool is engineered from the highest caliber tungsten carbide, ensuring exceptional hardness and wear resistance. The "DC" designation indicates a Double Cut flute geometry, which incorporates cross-cut teeth to reduce chip size. This design not only facilitates faster material removal but also minimizes tool chatter, providing the operator with greater control and a superior surface finish compared to single-cut alternatives.

One of the standout features of this specific model is its "L6" specification, denoting a 6-inch extended shank. Standard burrs often fail to reach deep into castings, pipes, or complex machinery housings. The 01V610 bridges this gap, allowing machinists and fabricators to deburr and finish areas that were previously inaccessible. The 1/4-inch shank is ground to precise tolerances, ensuring perfect concentricity. This balance is critical for high-speed die grinders, as it prevents vibration that can lead to premature tool failure or operator fatigue.

Walter Surface Technologies is renowned for quality, and this burr is no exception. It is suitable for use on a wide range of ferrous and non-ferrous metals, including stainless steel, steel alloys, and cast iron. Whether used for enlarging holes, smoothing contours, or general deburring, the 01V610 delivers consistent results. Its robust construction withstands high temperatures, maintaining its cutting edge longer than standard carbide bits. For industrial MRO operations requiring reliable, long-lasting tooling, this Walter carbide burr is an essential addition to the tool crib.

| Additional Information |

|---|

| Packaging Description:1 per each |

| Brand:Walter |

| Item:Carbide Burr |

| Length (in):6" |

| Diameter (in):3/8" |

| Shape:Ball (SD-3) |

| Cut Type:Double Cut |

| Shank Diameter:1/4" |

| Material:Tungsten Carbide |

| Application:Deburring, Enlarging Holes, Finishing |