Usually ships within 3-5 business days

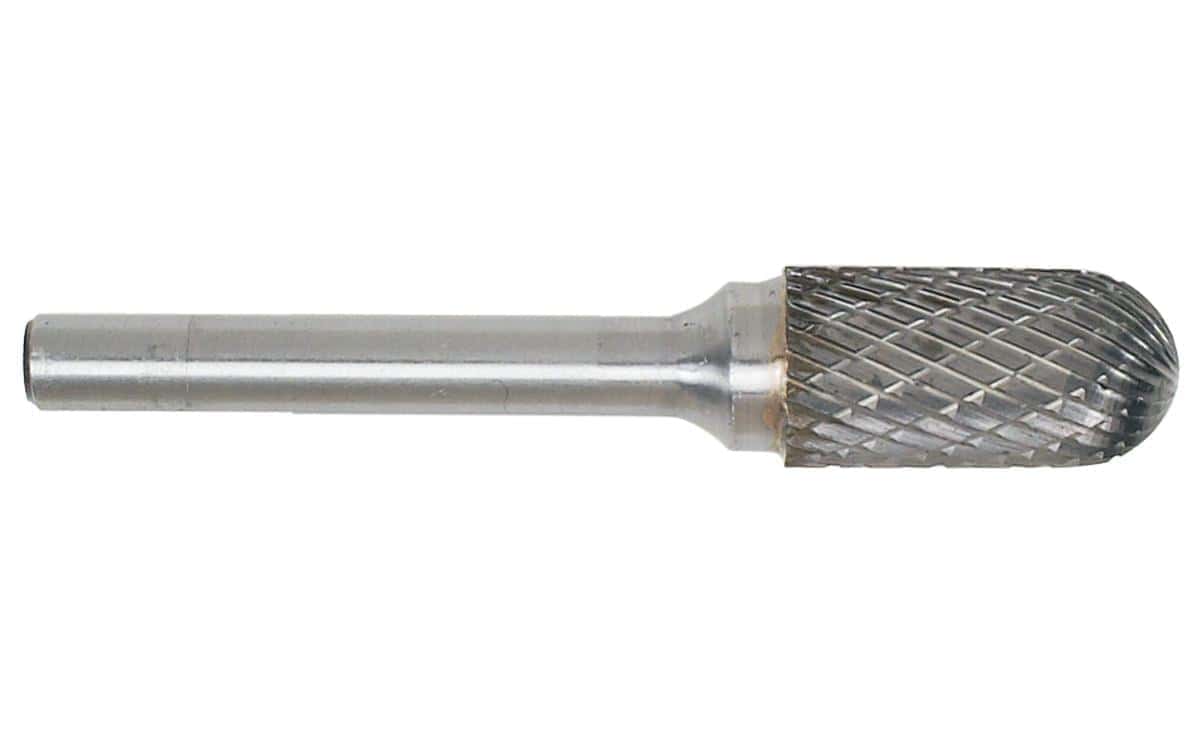

The Walter Carbide Burr SC-5 NF (01V008) represents the pinnacle of rotary file engineering, specifically tailored for the unique challenges of working with non-ferrous metals. Manufactured from the finest quality tungsten carbide, this tool is designed to deliver exceptional durability and wear resistance in industrial environments. The SC-5 shape, characterized by a cylindrical body with a radius end, offers versatile machining capabilities, allowing operators to grind both flat surfaces and contoured fillets with a single tool.

One of the critical features of this Walter burr is its impeccable concentricity. Precision balancing ensures that the burr runs true at high RPMs, significantly reducing vibration. This not only protects the bearings of your pneumatic or electric die grinder but also reduces operator fatigue during extended use. The reduction in chatter leads to a superior surface finish, minimizing the need for secondary polishing or sanding steps.

Standard carbide burrs often fail when applied to soft materials like aluminum, copper, or brass because the flutes pack with material, rendering the tool useless. The "Nf" (Non-Ferrous) designation on this Walter burr indicates a specialized open-flute design with a coarse pitch. This geometry promotes efficient chip evacuation, preventing the "loading" or clogging that plagues standard tools. By keeping the cutting edges clear, the tool maintains a consistent cutting action, ensuring maximum productivity and extended tool life.

Ideal for MRO (Maintenance, Repair, and Operations) and fabrication shops, this burr excels at enlarging holes, leveling weld seams, and deburring complex castings. The tungsten carbide substrate retains its hardness even at high operating temperatures, ensuring that the cutting edges remain sharp long after high-speed steel alternatives would have dulled. Whether you are working in aerospace, automotive, or general fabrication, the Walter SC-5 NF burr provides the reliability and precision required for professional results.

| Additional Information |

|---|

| Packaging Description:1 per each |

| Brand:Walter |

| Used to Grind:Non-ferrous metal, Aluminum |

| Item:Carbide Burr |

| Shape Code:SC-5 |

| Shape Description:Cylindrical with Radius End |

| Cut Type:Aluminum Cut, Non-Ferrous (NF) |

| Material:Tungsten Carbide |

| Head Diameter:1/2" |

| Length of Cut:1" |

| Shank Diameter:1/4" |