Usually ships within 3-5 business days

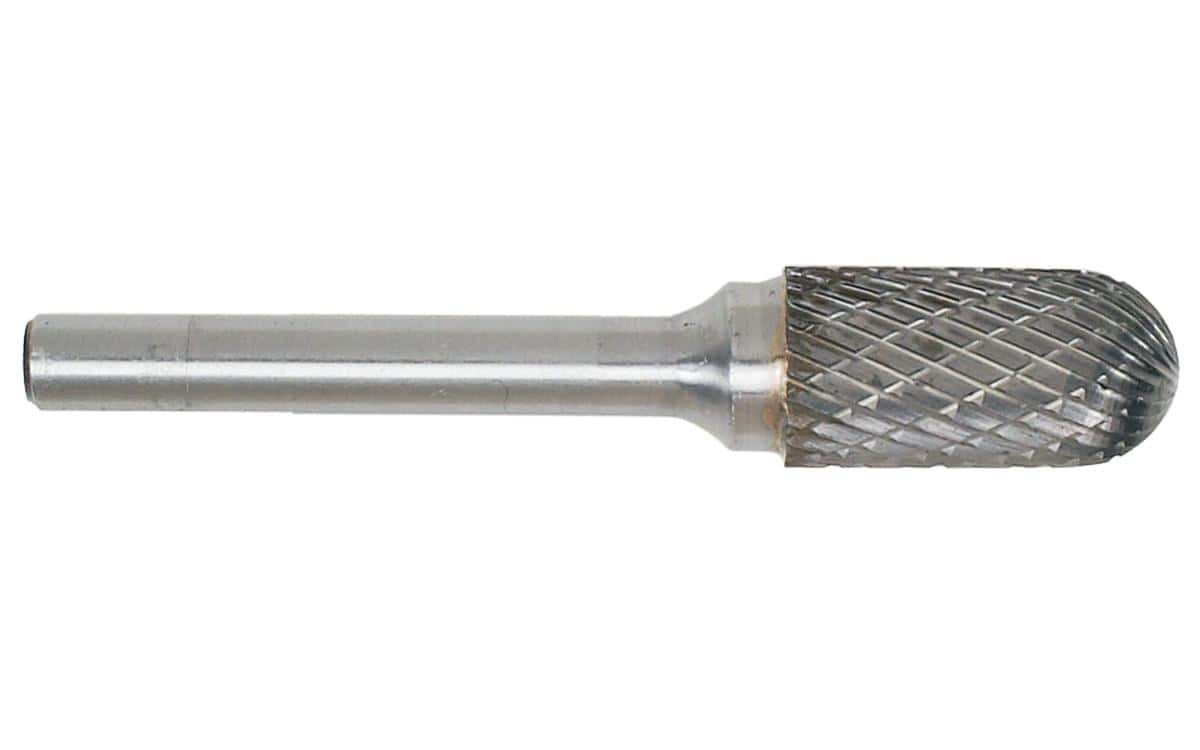

The Walter 01V607 is a high-performance tungsten carbide burr designed for industrial professionals who require precision, durability, and accessibility. This specific model features the SC-5 shape—a cylindrical head with a radius end—which is widely utilized for surface milling, contouring, and blending operations where a sharp corner is undesirable. The "L6" designation indicates a 6-inch extended shank, a critical feature for maintenance and fabrication tasks that involve deep cavities, long pipes, or obstructed areas where standard length burrs fall short.

Engineered with a Double Cut (DC) flute pattern, this burr excels in rapid material removal while maintaining operator control. The cross-cut design effectively breaks down chips into granular sizes rather than long, sharp slivers, significantly reducing the loading of the flutes and minimizing the "pulling" action often associated with single-cut burrs. This results in a smoother surface finish and reduced operator fatigue during prolonged use. The tool is manufactured from premium-grade tungsten carbide, ensuring it retains its cutting edge far longer than high-speed steel alternatives, even when processing hardened steels, stainless steel, and high-nickel alloys.

Walter Surface Technologies prioritizes concentricity in their manufacturing process. The 01V607 is precision ground to ensure perfect balance, which eliminates chatter and vibration at high RPMs. This balance is essential not only for the quality of the work but also for the longevity of the die grinder bearings and the safety of the operator. Whether used for enlarging holes, smoothing weld seams, or general deburring, this extended shank carbide burr delivers consistent, professional results in the most demanding industrial environments.

| Additional Information |

|---|

| Packaging Description:1 per each |

| Brand:Walter |

| Item:Carbide Burr |

| Used to Grind:Steel or Stainless |

| Shape:SC-5 (Cylindrical Radius End) |

| Cut Type:Double Cut |

| Shank Length:6" |

| Head Diameter:1/2" |

| Length of Cut:1" |

| Material:Tungsten Carbide |